- Products

- Catalogs

- News & Trends

- Exhibitions

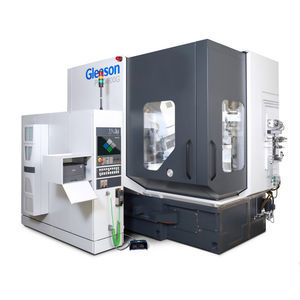

Computed tomography inspection machine 500CBfor gearsindustrialautomated

Add to favorites

Compare this product

Characteristics

- Technology

- computed tomography

- Applications

- for gears

- Sector

- industrial

- Other characteristics

- automated, measurement

Description

The 500CB delivers faster, more accurate, and highly automated build, truing and inspection of stick blade type bevel gear cutters.

Face milling cutter capacity (diameter), max. - 21"

Face hobbing cutter capacity (radius), max. - 210 mm

For All Stick Blade Cutter Systems

Automated cutter build, truing and inspection of Gleason and Non-Gleason stick blade type cutter systems.

Minimize Operator Involvement

Automated blade positioning and clamp screw torqueing to minimize operator involvement.

Greater Process Control

Absolute measurement and display of blade positioning.

Simple, Intuitive Operation

Simple, intuitive operation with adaptive process learns from previous builds.

Consistently High Quality

Consistently high cutter quality for improved tool life due to less operator influence.

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogsRelated Searches

- Inspection machine

- Automatic inspection machine

- Industrial inspection machine

- Optical inspection machine

- Measurement inspection machine

- Surface inspection machine

- Automated inspection machine

- 3D inspection machine

- CT inspection machine

- Gear inspection machine

- Cutting tool inspection machine

- Large part inspection machine

- Semi-automatic inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.