- Production Machines

- Cutting Machine

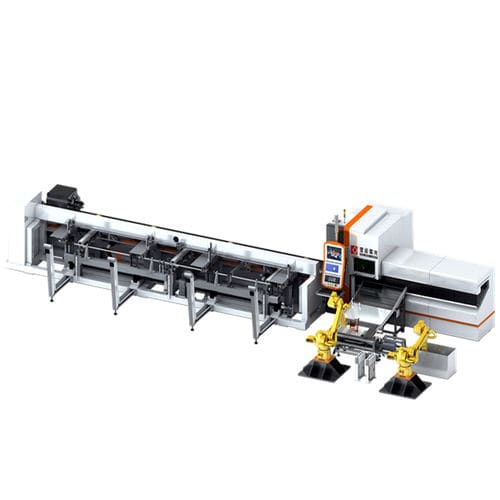

- Fiber laser cutting line

- Golden Laser Co., Ltd

Fiber laser cutting line i35Afor aluminumfor steelfor stainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for aluminum, for steel, for stainless steel, for brass, for copper, for iron, for carbon steel

- Product handled

- tube

- Control type

- CNC

- Associated function

- stacking, straightening, hole punch, bending, chamfering, deburring, marking, drilling, engraving, trimming

- Applications

- for industrial applications, with software optimisation, for aeronautical applications, for the automotive industry, for the food industry

- Workpiece loading

- automated loading/unloading

- Other characteristics

- high-speed, completely automated, high-precision, with automatic feeder, with conveyor, high-efficiency, for mass production, combined, large capacity, high-performance, precision, CE, with water cooling, high-power, custom-made, multi-axis

- Tube diameter

Max.: 350 mm

(14 in)Min.: 20 mm

(1 in)

Description

Laser tube cutting automatic flexible production line and feeding system is a customize project according to customer’s production line. We will choose the suitable tube laser cutting equipment and feeding system, robot to combine a unmanned operation production line. The advanced CNC controller to realize production line ERP management. Realize Zero stock production line.

Intelligent & automatic tube laser cutting production line for copper tube cutting and packing

Production line description:

(1) 2.5T Round tube quick auto bundle loader

(2) P series fully automatic tube laser cutting machine, it is equipped with full motorized floating support with can guarantee the high accuracy during the high cutting speed

(3) Receiving Belt

(4) Pneumatic Feeding Fixture

(5) Automatic robot for tube and cleaning

Fanuc M20iA quickly clean and brush the inner wall adhering slag

(6)Automatic robot unloading and packing

After cleaning, the Fanuc M20iA robot grabs and puts the cleaned tube into the packing box which can be filled with more than 3000 tubes.

(7)Fences and security doors

Using Omron safety switch, the whole machine complies with CE standards

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Other Golden Laser Co., Ltd products

Flexible Manufacturing System for Tube Processing

Related Searches

- Golden Laser cutting machine

- Golden Laser metal cutting machine

- Golden Laser CNC cutting machine

- Golden Laser laser cutting machine

- Golden Laser cutting machine for industrial applications

- Golden Laser automatic cutting machine

- Golden Laser high-precision cutting machine

- Golden Laser sheet metal cutting machine

- Golden Laser high-speed cutting machine

- Golden Laser fiber laser cutting machine

- Golden Laser tube cutting machine

- Golden Laser precision cutting machine

- Golden Laser aluminum cutting machine

- Golden Laser stainless steel cutting machine

- Golden Laser sheet cutting machine

- Golden Laser CE cutting machine

- Golden Laser metal fabrication cutting machine

- Golden Laser high-performance cutting machine

- Golden Laser cutting machine for the automotive industry

- Golden Laser high-efficiency cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.