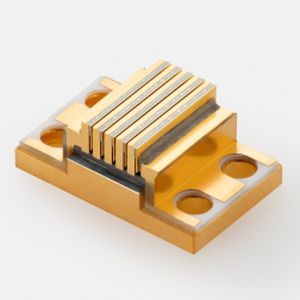

Laser light source L13920-511Mvisiblecompactfor fiber optics

Add to favorites

Compare this product

Characteristics

- Illumination technology

- laser

- Spectrum

- visible

- Other characteristics

- compact

- Technical applications

- for fiber optics

- Output power

30 W, 70 W

(0.04079 hp, 0.09517 hp)- Wavelength

940 nm

Description

The SPOLD built-in process monitor constantly captures thermal information on the laser irradiation point to allow quality control during laser processing, making it ideal for use in mass-production processes such as for plastic welding and soldering.

Features

• Transmitted laser light and thermal information with a single fiber simultaneously

• Thermal information of laser irradiation point can be acquired without any adjustment

• Compatible with galvano mirror system

• High speed 1 millisecond sampling to detect an instantaneous change

• Simplified processing peripheral parts by compact irradiation unit

Applications

• Plastic welding

• Adhesive thermal curing

• Soldering

• Other process or principle using laser as heat source

Catalogs

No catalogs are available for this product.

See all of HAMAMATSU‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Glass lens element

- HAMAMATSU LED light source

- SMT LED

- HAMAMATSU visible light source

- Spectrum lens element

- Lighting LED

- Lamp illuminator

- Visible lens element

- HAMAMATSU power LED

- Optical lens element

- HAMAMATSU photodiode

- BK7 lens element

- Round LED

- HAMAMATSU compact light source

- HAMAMATSU ultraviolet light source

- Square LED

- Spherical lens element

- HAMAMATSU PIN photodiode

- Infrared illuminator

- Laser diode

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.