- Building - Construction

- Construction and Mining Equipment

- Raymond mill

- Henan LIMING Heavy Industry Science and Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

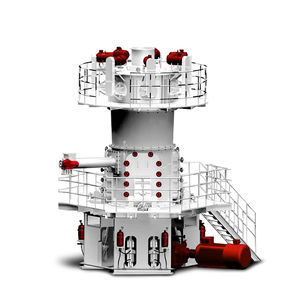

Raymond mill MTW145Gverticalsilicafor ore

Add to favorites

Compare this product

Characteristics

- Technology

- Raymond

- Orientation

- vertical

- Product applications

- silica, for ore, for cement, concrete, for clinker, stone, mica, quartz, kaolin, for limestone, for coal grinding

- Other characteristics

- compact, high-speed, high-performance, large, automatic, heavy-duty, air classifier

- Sector

- for the chemical industry

- Final grain size

Min.: 45 µm

Max.: 1,600 µm

- Rotational speed

Min.: 86 rpm

(540 rad.min-1)Max.: 110 rpm

(691 rad.min-1)- Output

Min.: 6 t/h

(4 lb/s)Max.: 23 t/h

(14 lb/s)- Motor power

Min.: 110 kW

(149.56 hp)Max.: 132 kW

(179.47 hp)- Machine length

8,971 mm

(353 in)- Machine width

9,630 mm

(379 in)- Machine height

11,185 mm

(440 in)

Description

MTW145G European Trapezium Mill

Large capacity, Low consumption, Environmental friendly

MTW European Trapezium Mill has a large market share in the grinding industry. Whether bevel gear overall drive, inner automatic thin-oil lubricating system or arc air channel, these proprietary technologies makes machine advanced, humanized and green.

Applications:

limestone desulfurization in power plant, heavy calcium carbonate processing, non-metallic mineral powder making, solid fuel grinding, building materials and chemical industry.

Performance Advantages

1. Mature technology and stable Performance: 4th generation mill, more than 30 years of mill manufacturing experience. Bevel gear overall drive provides strong power. the production capacity increased by 20% under the same power condition.

2. Economical and reliable: can grind a variety of minerals to meet the needs of different specifications of particle size; low investment cost, low operating cost, single machine processing capacity up to 60T/H.

3. Low cost, less maintenance: Patented technology, with Inner automatic thin-oil lubricating system, long oil change cycle, low frequency, low cost.

4. Scientific allocation, low energy consumption: Adjustable output size, efficient powder production. The vulnerable parts adopt special technology and material, more wear-resistant.

5. Environmental protection: unique air recycling system, together with advanced dust collector make environment much cleaner.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Henan LIMING Heavy Industry Science and Technology‘s catalogsOther Henan LIMING Heavy Industry Science and Technology products

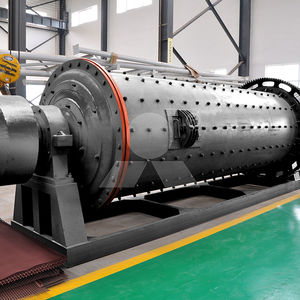

Grinding Mill

Related Searches

- Liming mill

- Liming crusher

- Liming stationary crusher

- Horizontal grinding mill

- Liming vertical mill

- Liming mobile crusher

- Liming impact crusher

- Liming jaw crusher

- Liming rotor mill

- Liming high-capacity crusher

- Liming primary crusher

- Liming roller mill

- Liming secondary crusher

- Liming building materials mill

- Liming mineral material crusher

- Liming compact crusher

- Crawler crushing and screening plant

- Liming cone crusher

- Liming building material crusher

- Liming mineral mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.