- Machine-tools

- Cutting Tool

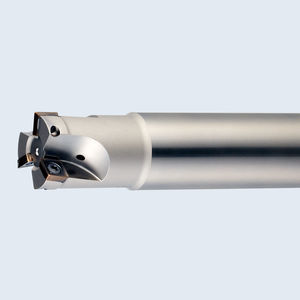

- Corner radius milling cutter

- MOLDINO Tool Engineering Europe GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Corner radius milling cutter TD4N seriesindexable insertfor cast ironfor stainless steel

Add to favorites

Compare this product

Characteristics

- Geometry

- corner radius

- Construction

- indexable insert

- Treated material

- for cast iron, for stainless steel, for hardened steel, for carbon steel

- Other characteristics

- high-performance, cutting edge, high-efficiency, screw-in

- Diameter

Min.: 10 mm

(0.39 in)Max.: 42 mm

(1.65 in)- Length

Min.: 25 mm

(0.98 in)Max.: 220 mm

(8.66 in)

Description

It is possible to reduce uncut parts and reduce the burden on the next process tool by up to 40% compared to conventional products. We have added inserts for machining hardened materials to our lineup.

Reduces uncut Work material

Useful chipbreaker and economical 4-cornered insert

Easy-to-use large tip diameter

Excellent chip evacuation

Catalogs

TD4N type

8 Pages

Other MOLDINO Tool Engineering Europe GmbH products

Indexable tool

Related Searches

- Moldino milling cutter

- Moldino solid milling cutter

- Moldino steel milling cutter

- Drilling tool

- Moldino clamping milling cutter

- Solid drilling tool

- Moldino milling cutter with cylindrical shank

- Moldino metal milling cutter

- Moldino insert milling cutter

- Moldino end mill

- Moldino coated milling cutter

- Moldino cast iron milling cutter

- Moldino cutting milling cutter

- Moldino ball nose milling cutter

- Shell-end milling tool

- Moldino roughing milling cutter

- Face milling tool

- Moldino corner radius milling cutter

- Carbide drilling tool

- Moldino indexable insert milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.