- Machine-tools

- Cutting Tool

- Ball nose milling cutter

- MOLDINO Tool Engineering Europe GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

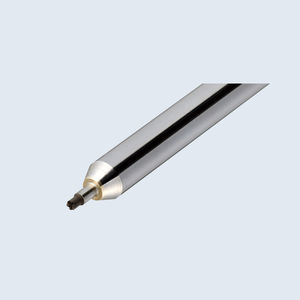

Ball nose milling cutter EPSB2 seriesend millsolidfinishing

Add to favorites

Compare this product

Characteristics

- Geometry

- ball nose, end mill

- Construction

- solid

- Type

- finishing, semi-finishing

- Material

- CBN

- Treated material

- for hardened steel

- Other characteristics

- high-precision, cutting edge, with cylindrical shank, cutting

- Diameter

Min.: 0.2 mm

(0.01 in)Max.: 2 mm

(0.08 in)- Length

50 mm, 55 mm

(1.97 in, 2.17 in)

Description

Cutting resistance is low, so the finishing surface is excellent and finish accuracy is higher.

Fine (F) type: Prioritizes high-accuracy machining

Strong (S) type: Prioritizes stable machining

Two types of geometry are available for sharpness of cutting edge and rigidity, enabling the geometry type to be selected according to the machining application.

Recently, the trend in mold has been toward harder and harder materials, and cutting such materials has become very difficult. In addition, in order to respond to demands for ultra-high precision, tool wear resistance has become very important, and recently tool materials other than carbide, such as CBN, etc., are receiving a lot of attention. The geometry of this newly developed Epoch CBN End Mill series, unlike the conventional geometry commonly seen on most CBN tools which focuses on rigidity, achieves both rigidity and good sharpness of cutting edge.

In this way, it enables high-precision finishing machining over a long period of time on high-hardness materials.

Features and Applications

❶ Can be used as easily as carbide end mills while reducing wear.

❷ Cutting edge shape takes care of chipping, which is a problem with CBN materials, enabling stable finishing for a long time.

❸ Biting characteristics are the same as those of carbide end mill but cutting resistance is reduced, so finish accuracy is improved.

❹ Long life even when direct cutting high hardness materials of 60HRC or higher.

❺ Ideal for small-work machining, with a lineup of ball end mills in sizes from RE0.1 to RE1mm and radius end mills in sizes from φ0.5 to φ3mm. (Under neck length: up to 10DC)

Catalogs

No catalogs are available for this product.

See all of MOLDINO Tool Engineering Europe GmbH‘s catalogsOther MOLDINO Tool Engineering Europe GmbH products

Endmills

Related Searches

- Moldino milling cutter

- Moldino solid milling cutter

- Moldino steel milling cutter

- Drilling tool

- Moldino clamping milling cutter

- Solid drilling tool

- Moldino milling cutter with cylindrical shank

- Moldino metal milling cutter

- Moldino insert milling cutter

- Moldino end mill

- Moldino coated milling cutter

- Moldino cast iron milling cutter

- Moldino cutting milling cutter

- Moldino ball nose milling cutter

- Shell-end milling tool

- Moldino roughing milling cutter

- Face milling tool

- Moldino corner radius milling cutter

- Carbide drilling tool

- Moldino indexable insert milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.