- Production Machines

- Cutting Machine

- Laser cutting machine

- JAITAI LASER SCIENCE AND TECHNOLOGY CO,.LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

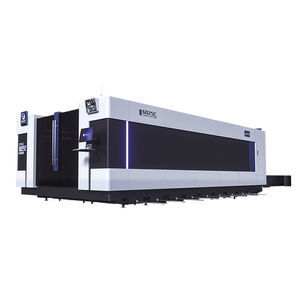

Laser cutting machine JTLC6025 seriesfor metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Applications

- for construction machinery, for industrial applications, for the automotive industry, for aeronautical applications, for the food industry, for industrial vehicles, for agricultural vehicles, for kitchenware industry, for shipbuilding, for the aerospace industry, for bathroom sanitary ware industry

- Configuration

- gantry type

- Other characteristics

- automatic, high-precision, linear

- X travel

3,000 mm, 4,000 mm, 6,000 mm

(118 in, 157 in, 236 in)- Y travel

1,500 mm, 2,000 mm, 2,500 mm

(59 in, 79 in, 98 in)- Cutting speed

Max.: 196,000 mm/min

(128.609 in/s)Min.: 0 mm/min

(0 in/s)- Laser power

3,000 W, 4,000 W, 6,000 W, 8,000 W

- Acceleration

Max.: 50 m/s²

(164 ft/s²)Min.: 30 m/s²

(98 ft/s²)- Overall length

10,700 mm

(421 in)- Overall width

3,550 mm

(140 in)- Height

2,300 mm

(91 in)

Description

The LC series cutting machine adopts a new blue and white design. With an intelligent system which is more convenient to operate. greatly reduces operating costs. simplifies manual labor. and can be used in an industrial environment; long life. high processing accuracy, and fast speed; high power conversion efficiency , lt can realize intelligent, automatic and flexible operation.

l. Adopting gantry double-drive structure, high-precision reducer, rack and pinion and linear guide, stable transmission, fast acceleration and high positioning accuracy.

2. One-key calibration, automatic edge finding, automatic typesetting, leapfrog and other powerful technological functions to simplify the operation process

3. Patented machine tool design, good cutting quality, small thermal deformation, smooth cutting surface,flat and beautiful

4. Use professional CNC cutting software to design various graphics or text at will, flexible processing and simple operation

Product structure

The bed adopts an integral welded structure After annealing to eliminate internal stress, it is rough-machined, and it is finished after secondary vibration aging treatment, which can better solve the stress caused by welding and processing, thereby greatly improving the machine tool's performance. stability.

The X, Y, and Z axes are all imported from Germany with servo motors. equipped with high-rigidity precision reducer, high-precision rack and pinion. high-precision linear guide and other efficient transmission mechanisms, which effectively ensure the accuracy of transmission.

Other JAITAI LASER SCIENCE AND TECHNOLOGY CO,.LTD products

Plate Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- High-performance cutting system

- Cutting machine for the automotive industry

- Compact cutting system

- High-efficiency cutting system

- Bridge cutting system

- Carbon steel cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.