- Production Machines

- Cutting Machine

- Knife cutting machine

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

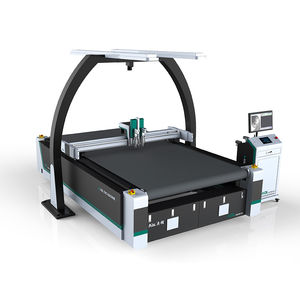

Cutting machine for medical applications ZS seriesknifefor fabricssheet

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Material

- for fabrics

- Product handled

- sheet

- Control type

- with digital assistance

- Applications

- for medical applications

- Configuration

- double-head

- Other characteristics

- automatic, high-precision, high-performance, high-efficiency, with servo-motor

- X travel

1,600 mm, 1,800 mm

(63 in, 71 in)- Y travel

2,500 mm

(98 in)- Cutting speed

Max.: 2,000 mm/s

Min.: 200 mm/s

Description

Medical industry material cutting machine | AOL cutter

High-quality material cutting in the medical industry should be matched with a medical industry material cutting machine that can cut high-quality results. It is the best choice to triple the cutting efficiency and save 30% of the material cost. The automation equipment liberates the body and mind and reduces labor costs.

Advantages of AOL Medical Material Cutting Machine

1. The cold cutting method using blades has zero environmental pollution.

2. Using Taiwan’s linear guide, the accuracy is ±0.1mm, and the high accuracy guarantees the cutting quality.

3. The AOL cutting system is equipped with an intelligent layout optimization module, which continuously optimizes the cutting pattern filling, which can save up to 30% of the material cost.

4. Japan’s Panasonic servo motor system provides lasting and stable cutting power to ensure the consistency of cutting quality.

5. Flexible tool replacement can cut more materials and provide more industry development possibilities.

6. Intelligent desktop height compensation, AOL cutting machine can automatically detect the desktop height, for desktop height consistency, it can automatically perform desktop compensation.

Materials that can be applied

Most of the medical industry consumables are made of non-woven materials, such as surgical gowns, bio-paper, gauze, protective clothing, etc., flexible materials in the medical industry, AOL CNC cutting machine can achieve perfect cutting for you .

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan AOL CNC Equipment Co., Ltd‘s catalogsOther Jinan AOL CNC Equipment Co., Ltd products

Digital Fabric Cutting machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- CE cutting system

- High-performance cutting system

- Cutting machine for the automotive industry

- High-efficiency cutting system

- Compact cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.