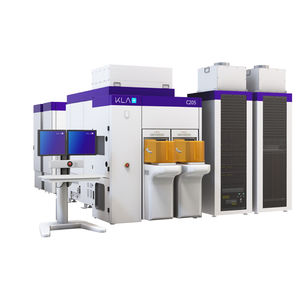

Optical inspection machine CIRCL™ for wafersfor the electronics industrymacro defect

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Applications

- for wafers

- Sector

- for the electronics industry

- Other characteristics

- macro defect

Description

All-Surface Wafer Defect Inspection, Metrology and Review Cluster System

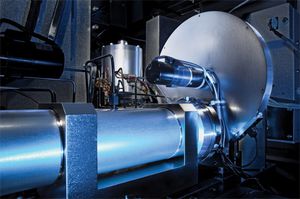

The CIRCL™ cluster tool has four modules, covering all wafer surfaces and providing parallel data collection at high throughput for efficient process control. The modules comprising the latest-generation CIRCL5 system include: front side wafer defect inspection; wafer edge defect inspection, profile, metrology and review; backside wafer defect inspection and review; and, optical review and classification of front side defects. Data collection is controlled by DirectedSampling™, an innovative approach that uses results from one measurement to trigger other types of measurements within the cluster. The modular configuration of CIRCL5 offers flexibility for varying process control needs, saves overall fab space, reduces wafer queue time, and provides a cost-effective upgrade path to protect a fab's capital investment.

Applications

Process monitor, Outgoing Quality Control (OQC), Tool monitor, Backside monitor, Edge yield monitor

Catalogs

No catalogs are available for this product.

See all of KLA - TENCOR‘s catalogsRelated Searches

- Inspection machine

- Automatic inspection machine

- Defect inspection machine

- Optical inspection machine

- Measurement inspection machine

- Surface inspection machine

- Inspection machine for the electronics industry

- Automated inspection machine

- High-resolution inspection machine

- Wafer inspection machine

- Macro defect inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.