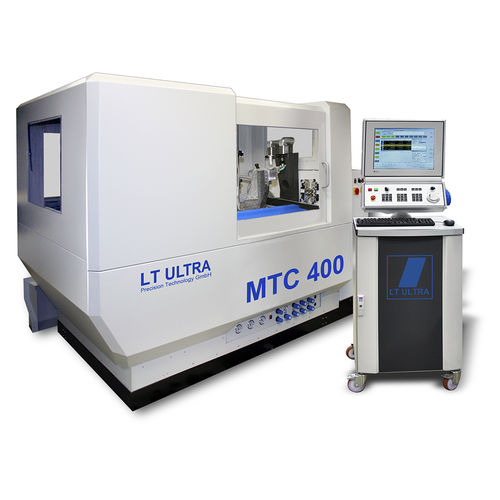

CNC turning machine MTC 4002-axis4-axisfor metal

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis, 4-axis

- Applications

- for metal

- Other characteristics

- hydrostatic, with linear motor

- Diameter

800 mm

(31.5 in)- Spindle speed

2,000 rpm

(12,566.371 rad.min-1)- Axe X

400 mm

(16 in)- Axe Z

400 mm

(16 in)

Description

Single point machining

Granite machine base

Active vibration isolation system

Form measuring system

Integrated tool measuring System

Process camera

- Form tolerance: 100 nm within 100 mm dia.

Roughness: 2 nm (Ra)

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg.

The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

VIDEO

Catalogs

MTC 400

2 Pages

Other LT Ultra-Precision Technology GmbH products

Turning machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.