- Machine-tools

- Machining Center

- 5-axis machining center

- MAKINO Milling Machine

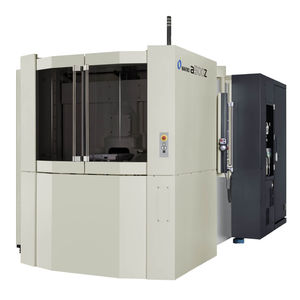

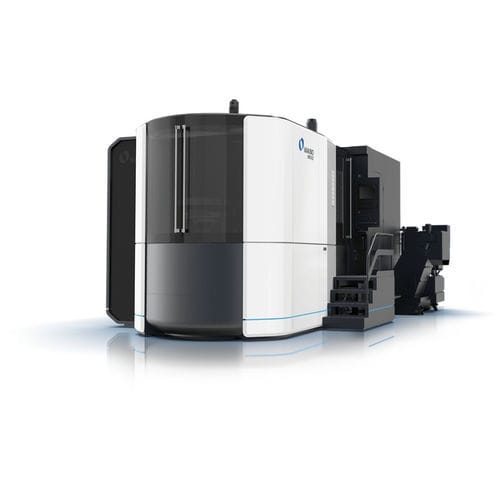

5-axis CNC machining center a800Zhorizontalfor the aerospace industryfor production

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for the aerospace industry

- Other characteristics

- for production

- X travel

1,280 mm

(50 in)- Y travel

1,200 mm

(47 in)- Z travel

1,325 mm

(52 in)- Rotational speed

Max.: 10,000 rpm

(62,832 rad.min-1)Min.: 20 rpm

(126 rad.min-1)- Work feed X-axis

Max.: 50,000 mm/min

(33 in/s)Min.: 1 mm/min

(0 in/s)- Work feed Y-axis

Max.: 50,000 mm/min

(33 in/s)Min.: 1 mm/min

(0 in/s)- Work feed Z-axis

Max.: 50,000 mm/min

(33 in/s)Min.: 1 mm/min

(0 in/s)- Table load capacity

1,000 kg

(2,205 lb)

Description

The a800Z is a horizontal machining centre that adds 5X capabilities to the highly successful a81nx machine. Featuring the same power, performance and reliability as the a81nx, the new a800Z will prove an attractive investment for production applications in the e-vehicle, internal combustion engine, agricultural vehicle, semiconductor and aerospace industries.

Z-type table

It is not just the spindles that stand out on the new a800Z. Its Z-type agility tiling table brings the centre of gravity of the table and the workpiece close to the centre of rotation of the tilting axis. As a result, inertia is minimised while positioning movements can be performed at high speed and with great accuracy. In other words, this oversized table – in itself an advantage – plays a key role in enabling fast and accurate 5X machining.

Excellent chip evacuation

No machine operator wants chips accumulating in the machining chamber. That is why the a800Z has a high-capacity chip management system. The interior walls of the machining chamber are in stainless steel to minimise chip adherence. Besides, these close-to-vertical walls allow chips to freely fall by their own weight. Three evacuation channels at the bottom of the chamber ensure efficient chip evacuation to the standard high-capacity chip conveyor. Such efficiency avoids energy losses and reduces coolant tank maintenance.

Economical coolant use

Disposing of the fine chips and sludge generated in machining processes is problematic, as contaminated coolant is hardly an eco-friendly liquid. In the a800Z an agitator in the coolant tank prevents the particles from settling and accumulating.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- BT 40 CNC machining center

- Horizontal CNC machining center

- Compact CNC machining center

- Machining center for the automobile industry

- EDM

- Turning-milling machine

- CNC turning-milling center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.