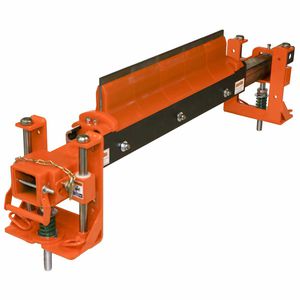

Tungsten carbide secondary conveyor belt cleaner DT2Sstainless steelurethane

Add to favorites

Compare this product

Characteristics

- Material

- tungsten carbide, stainless steel, urethane

Description

Martin® DT2S Reversing Secondary Cleaner fits in narrow spaces. Slide-in/slide-out blade assembly allows quick belt cleaner service, minimizing downtime.

Features and Benefits:

• Slide-in/slide-out belt cleaner blade cartridge allows quick and easy blade service that minimizes conveyor downtime. Even when the cleaner is encrusted with material, one-half of the split frame can be removed to allow blade change

• Effective belt cleaning reduces plant cleanup chores and prolongs life of conveying equipment

• Can be installed on conveyors that roll back or run in two directions with proper blade selection

• Lean profile minimizes space requirements, allows installation in spaces as narrow as seven inches (178 mm)

Applications:

• Suited for medium to heavy-duty applications, on belts from 24 to 96 inches (~500 to 2400 mm) operating at speeds up to 900 fpm (3.5 m/sec)

Options:

• Martin Engineering’s color-coded high performance urethanes available to suit application

• Available with tungsten carbide reversing blade, stainless steel reversing blade, INLINE tungsten carbide blade and urethane reversing blade

• Martin® Air Tensioner or Spring Tensioner available

Our technicians and engineers are available to provide expert advice and assistance on this product and all of your bulk material handling questions and problems. Please contact us today and let us help!

Catalogs

BELT CLEANERS

24 Pages

Related Searches

- Vibration motor

- Pneumatic vibrator

- Concrete vibration motor

- Electric vibration motor

- Rotary vibration motor

- Hopper vibration motor

- Silo vibration motor

- Industrial vibration motor

- High-frequency vibration motor

- Multi-product vibrator

- Ram vibrator

- Turbine vibrator

- Explosion-proof vibration motor

- Three-phase vibration motor

- Impact piston vibrator

- Ball vibrator

- Bulk material vibrator

- Compact vibrator

- Portable vibration motor

- Conveyor belt pre-cleaner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.