- Industrial machines and equipment

- Welding and Assembly

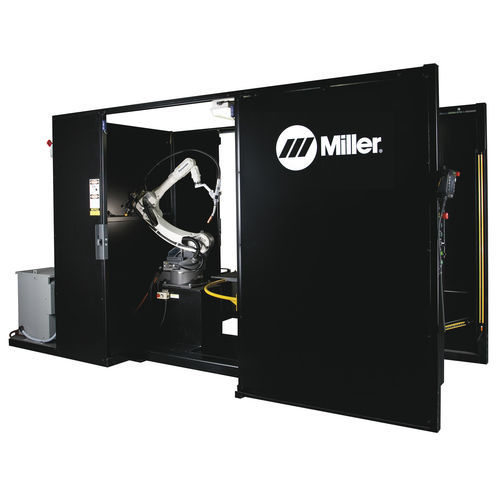

- Robotic welding cell

- Miller Electric Mfg.

- Products

- Catalogs

- News & Trends

- Exhibitions

Robotic welding cell PerformArc 350Sassemblyfor machining centershigh-flexibility

Add to favorites

Compare this product

Characteristics

- Function

- for welding, assembly

- Applications

- for machining centers

- Other characteristics

- high-flexibility

Description

High Output System for Automotive or General Manufacturing Parts

Small system fits in tight spots around the shop.

Extremely high output-to-investment ratio.

GMAW or GTAW applications

Setting the standard in the welding industry for quality, reliability and productivity since 1996. The PerformArc is backed by Miller today and tomorrow

Turntable rotates 180 degrees in under 2.2 seconds! Minimizing index time and maximizing productivity.

Support Hotline provides customer service and parts support.

Completely pre-wired and pre-assembled, eliminates assembly time.

Easy to locate and connect the utilities.

AccuPulse

AccuCurve

SP-MAG II

100% CO2

RMD

Active Wire Process -low energy short circuit and zero spatter.

GMAW-P

GTAW -with and without filler Aluminum -low pulse, dual pulse, synchronized weaving

Sevo Push-Pull Torch

Arc Data Monitoring

Offline Programming -DTPS

Control panel and full color teach pendant provide full system control, diagnostics and programming capability in one central location.

Designed in accordance with ANSI/RIA R15.06-2012, UL1740, NFPA 79 and CSA Z434.

L-shaped light curtains, interlocked safety gates, dual channel safety circuit, rotating arc flash barrier and solid sheet metal wall panels.

Catalogs

PerformArc 350S

2 Pages

Related Searches

- Welding system

- Miller welder

- Miller arc welder

- Miller portable welder

- Arc welding system

- Inverter welder

- Industrial fume extractor

- Miller MIG-MAG welder

- Miller three-phase welder

- Metal welding system

- Miller single-phase welder

- Miller DC welder

- SMAW welder

- Arc welding torch

- Miller TIG welder

- Robotic cell

- Mobile fume extractor

- Manual welding system

- Welding fume extractor

- Miller welder with integrated display

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.