- Metrology - Laboratory

- Analytical Instrumentation

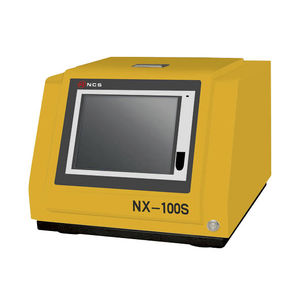

- Sulfur analyzer

- NCS Testing Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Carbon analyzer CS-3000Gsulfurconcentrationbenchtop

Add to favorites

Compare this product

Characteristics

- Measured entity

- carbon, sulfur

- Measured value

- concentration

- Configuration

- benchtop

- Technology

- infrared

Description

CS-3000G Dual Combustion Furnace Infrared Carbon and Sulfur analyzer uses resistance furnace and high-frequency induction combustion furnace, adopts infrared absorption method, can quick and accurate analyze the mass fraction of carbon and sulfur in steel, cast iron, alloy, metallic ore, ceramic, cement, lime, rubber, coal, coke, refractory materials, carbide, graphite, oil products, catalysts, soil and other solid materials .

Features:

Infrared Detection System:

1) Upon the needs of users, the carbon and sulfur analyzer with standard configuration is equipped with three separate infrared absorption cells.

2) Detector: The pyroelectric solid-state infrared detector produced in Germany is applied.

3) Dynamo: The synchronous dynamo produced in Switzerland is applied.

4) Light Source: The stable anti-oxidation infrared light source produced in the US is applied.

5) Constant Temperature: The entire chamber is thermostatically controlled to ensure constant analysis temperature for the accuracy of detection.

Flow control:

High-precision electronic flow control technology with the Anti-Overshoot System is adopted for flow control of analysis gas.

Catalytic Oxidation in the Copper Furnace:

1) Before channeled to Carbon detection cell, the analysis gas goes through catalytic oxidation in the copper furnace to turn CO in the analysis gas to CO2 to ensure all CO and CO2 generated in the combustion process can be detected.

2) Change the analyzed SO2 into SO3 and then absorb SO3 to avoid air pollution.

Catalogs

Other NCS Testing Technology Co., Ltd. products

Testing Instruments

Related Searches

- Gas analyser

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Desktop analyzer

- Dust analyzer

- Spectrometer

- Integration analyser

- Oxygen analyser

- NDIR analyzer

- Laboratory spectrometer

- Analyser for the food industry

- Quality control analyser

- Process spectrometer

- Optical spectrometer

- Mass spectrometer

- Conductivity analyser

- Hydrogen analyser

- Nitrogen analyser

- Sulfur analyser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.