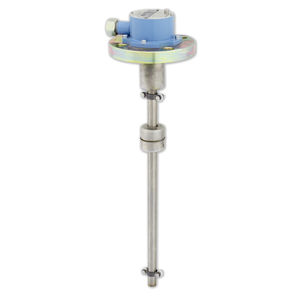

Magnetic float level sensor PMP-201for liquidsModbusfor storage tanks

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic float

- Medium

- for liquids

- Interface

- Modbus

- Applications

- for the food industry, for storage tanks, for fill monitoring, fuel tank, for medical applications, for industrial applications, for OEM, for corrosive environments, for hygienic applications, for the food and beverage industry, for hazardous areas, for food applications

- Other characteristics

- stainless steel, maintenance-free, high-precision, rugged, flange-mount, submersible, programmable, chemical-resistant, explosion-proof, corrosion-resistant, IP66, with temperature measurement

- Level range

Min.: 500 mm

(19.69 in)Max.: 6,000 mm

(236.22 in)- Process pressure

Min.: 1 bar

(14.5 psi)Max.: 25 bar

(362.59 psi)- Process temperature

Min.: -50 °C

(-58 °F)Max.: 60 °C

(140 °F)

Description

Designed for measurement and control of liquid media parameters, including explosive media, during accounting and process operations.

Used in different systems of commercial accounting of petroleum products as well as in different industrial automation systems in oil and gas, chemical, food and municipal industries.

Main operation sites: Oil and gas stations, tank farms, Oil and gas filling terminals and refineries.

• - transmits processed values of measured parameters

• - shock-resistant housing made of aluminum alloy or corrosion-proof steel

• - explosion-proof modification

• - inverted modification for installation at tank bottom

• - easy operation and commissioning

• - transit connection

• - transport modification for mobile tanks including naval and riverine vessels

• - chemical-proof modification for liquids with high chemical activity

• - continuous self-testing

• - various types of mounting devices for protective cable sheath (metal hose conduit, armored cable, pipe)

The housing is manufactured is alluminium alloy AlSi7 with fluoride oxide electroconductive coating and powder-coated (might be manufactured of stailess steel as per Customer’s request). External grounding clamp, single or two cable entries. Can be completed with various cable protection sheaths fixture units. Electric board with terminals is placed inside the protective housing. The access to the board is provided with removable lid.

Tank fixture fitting is manufactured according to Customer’s requirements.

Catalogs

Related Searches

- Pressure gauge

- Level probe

- Liquid level probe

- Analog pressure indicator

- Pressure probe

- Analog level probe

- Level transmitter

- Digital output level sensor

- Liquid level transmitter

- Analog level transmitter

- Analog pressure probe

- Waterproof pressure gauge

- Storage tank level probe

- Liquid level indicator

- Stainless steel level probe

- Digital output level transmitter

- Stainless steel pressure probe

- RS-485 level probe

- Sensitive element pressure sensor

- Visual level indicator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.