- Products

- Catalogs

- News & Trends

- Exhibitions

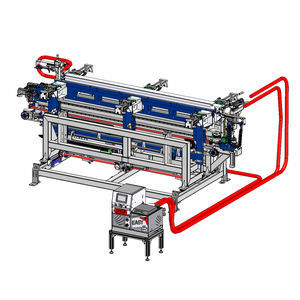

Automatic cardboard box/case erector FM410hot-melt glue

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Technology

- hot-melt glue

- Throughput

8 p/min, 10 p/min

Description

This machine is designed to automatically form the bottom of boxes FEFCO 410 .

An automatic centring device is always provided at the machine inlet to ensure that the box is correctly aligned.

At the first station the four head flaps are erected and glued with hot glue to form the first part of the box tray.

In the second station the remaining four back flaps are then folded and glued with hotmelt glue. Once these two steps are completed, the bottom of the box is formed, and the item can be placed inside.

The cardboard feeding can be handled manually, automatically from pallets or via a die-cutting machines.

The short set-up and format changeover time make this machine suitable for both production in large batches and lot size 1.

Technical features

Productivity rate : L 1301 to 2500 mm up to 8 pcs/min

L 400 to 1300 mm up to 10 pcs/min

Item size : MIN: L.400 X W.220 X H.30

MAX: L.2500 X W.1200 X H. 250

Type of box : F410

Cardboard type : Cardboard thickness: min 2 – max 7 mm

Catalogs

No catalogs are available for this product.

See all of Panotec‘s catalogsRelated Searches

- Complete packaging line

- Case sealer

- Cardboard box/case erector

- Automatic complete packaging line

- Automatic cardboard box/case erector

- Automatic case sealer

- Adhesive tape cardboard box/case erector

- Hot-melt glue cardboard box/case erector

- Label printer-applicator

- High-speed cardboard box/case erector

- Pneumatic cardboard box/case erector

- Self-adhesive label printer-applicator

- Hot-melt glue case sealer

- Multi-product complete packaging line

- Fully-automatic complete packaging line

- High-speed complete packaging line

- Compact complete packaging line

- Case former-sealer

- Adhesive tape case former-sealer

- Packaging label printer-applicator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.