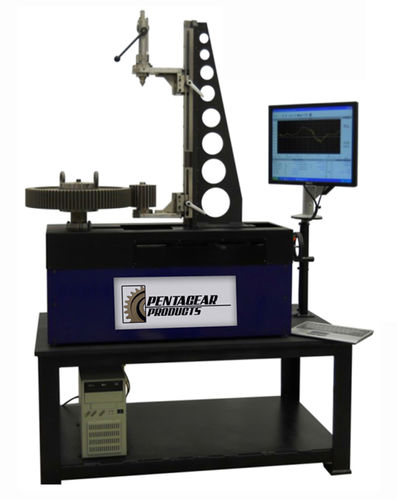

Gear inspection machine DFT 500measurement

Add to favorites

Compare this product

Characteristics

- Applications

- for gears

- Other characteristics

- measurement

Description

Double Flank gear testing is considered a composite testing approach to gear measurement. It measures the “composite” of Index, Helix (lead), Profile and Runout errors in a gear.

Double flank testing consists of rolling two gears together in tight mesh (preloaded one against another without backlash) and measuring the center distance deviation as the parts rotate 360°. One of the gears in mesh is a master gear with very small elementals errors and the other is the component to be tested. After rotating for 360°, a chart is created showing the center distance variation between the two gears.

Characteristics to Test

Total Composite Error Fi”

Tooth-to-Tooth Error fi ”

Composite Runout Error Fr”

Mean Center Deviation da”

Nicks and Burrs

50-200 mm center distance

Linear scale 1 micron resolution

Windows 7

Minimal operator training required

Direct drive rotary motor with encoder

Computer system with:

Double flank analysis for AGMA, DIN, ISO and custom

Optional force gage integrated

Max part weight 450 lbs.

Max gear 50″

Max length between centers 20″

Catalogs

DFT500

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.