Plasma surface treatment machine for filmfor the printing industry

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- for film, for the printing industry

Description

To be able to print and coat plastic films, the surface tension of the material must first be increased. In addition, coating requires long-term stability of surface activation. In the methods previously available, such as corona treatment or flame treatment, surface tension decreases after a short time.

Pretreatment with the Openair® process results in reliable surface activation of the plastic films – activation that displays outstanding long-term stability. Inks and coatings are optimally absorbed.

Openair® film systems use special slot nozzles. They it make possible to reliably treat film with atmospheric-pressure plasma over any width. An additional positive side effect of treating the plastic with Openair® plasma is a noticeable anti-static effect.

Openair® plasma systems for the treatment of plastic films – advantages and properties:

Pretreatment with long-term stability due to high surface activation

Possibility of partial activation

Additional cleaning effect of additives

Anti-static effect

Treatment width per nozzle = 25 mm

Single-sided pretreatment

High processing speeds

Catalogs

No catalogs are available for this product.

See all of Plasmatreat‘s catalogsRelated Searches

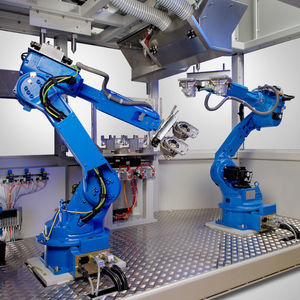

- Industrial robot

- Articulated robot

- 6-axis robot

- Handling robot

- Compact robot

- Cleaning atomizing nozzle

- Plastic nozzle

- Surface treatment machine

- Hollow-cone nozzle

- Plasma surface treatment machine

- PP nozzle

- Rotary atomizing nozzle

- Surface treatment robot

- Glue nozzle

- Aluminium nozzle

- Surface treatment machine for the printing industry

- Plasma generator

- Surface treatment nozzle

- Outlet nozzle

- Rubber nozzle

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.