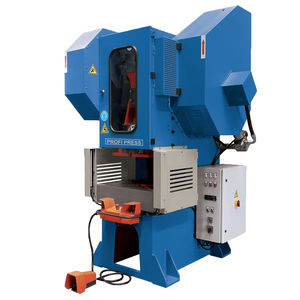

Mechanical press PPE-4-160stampingdeep drawingpunching

Add to favorites

Compare this product

Characteristics

- Operation

- mechanical

- Function

- stamping, deep drawing, punching, cutting

- Structure

- C-frame

- Control

- PLC-controlled, NC

- Other characteristics

- with pedal control

- Applications

- for the aerospace industry, for automotive applications

- Force

160 tf

- Rate (strokes/min)

45 p/min

- Stroke

Max.: 150 mm

(6 in)Min.: 20 mm

(1 in)- Table width

700 mm

(28 in)- Table length

1,100 mm

(43 in)- Overall length

1,800 mm

(71 in)- Overall width

1,860 mm

(73 in)- Overall height

3,200 mm

(126 in)

Description

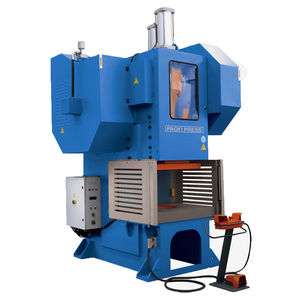

This C-frame Power Press has a capacity of 160 tons and is suitable to carry out tasks involving deep-drawing, cutting, punching and stamping. Our Profi Press mechanical presses can be used for various applications in many different industries: the automotive, railway and aerospace industries (for example) and many more related industries that use metal forming.

Made of S355JR steel and equipped with a 4 guided ram. The rod is made out of high-strength forged steel and high-performance alloy bushings. This high performance Profi Press features a central motorized lubrication system, overload protection and an electropneumatic clutch-brake combination.

RHTC produces the C-frame power press in Europe and we deliver all these presses in accordance with the latest CE standards. High quality guaranteed!

Central motorized lubrication system to guarantee a perfect performance and maintenance

Hydraulic overload protection to protect the machine components and installed tools

Electro-pneumatic clutch and brake combination equipped with a dual safety solenoid valve. This system includes a compensation tank, a regulator-lubrication filter and a pressure control switch

Lateral protection screens with level IV safety light guards

Programmable control system (PLC)

Adjustable stroke

Anti-vibration pads

Operation by means of two-hands push-button control as well as a foot pedal

Inverter (speed variation)

Pneumatic or hydraulic die ejector or cushion

Lower auxiliar table

Strain gauge system

NC digital display with memories to save various working cycles

Catalogs

RHTC Catalogue 2021

56 Pages

RHTC Catalogue 2022 - 2023

56 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Industrial press

- Hydraulic press

- Forming press

- Automatic press

- Pneumatic press

- Punching press

- Punching center

- Electric press

- Manually-controlled press

- Cutting press

- Stamping press

- Mechanical press

- PLC-controlled press

- Production press

- Automatic punching press

- C-frame press

- Drilling press

- Press for the automotive industry

- NC press

- Sheet metal punching machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.