- Production Machines

- Forming Machine

- Bending die

- ROLLERI S.P.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

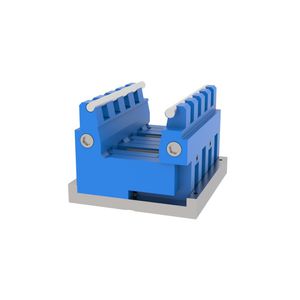

Bending die RVT55-1 series

Add to favorites

Compare this product

Description

Rolla-V die RVT series in 42 Cr. Max.load 1000 kN/m. Minimum angle 35°.

The Rolla V dies are distinguished from the traditional ones by the presence of 2 oscillating rotors which support the sheet metal before the bending process. Their peculiarity consists in the rotation of the rotors that accompanies the sheet metal during the bending with a drastic reduction of the friction resistance and of the length of the minimum edge. This type of tool applies the concept of tangential bending whereby the behavior of the sheet is different: this is more noticeable if holes and slots are present near the bending areas. Thanks to this concept, these areas do not undergo the classic deformations more commonly known as "slurries".

Sheet metal supported during bending process

Minimum movement of the sheet metal on the inserts reduces bending marks

Internal bending radius is the same of the punch tip radius

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.