- Production Machines

- Plastics Processing

- Hot-runner plastic injection mold

- Sino Mould Co.,Ltd Huangyan Taizhou

- Products

- Catalogs

- News & Trends

- Exhibitions

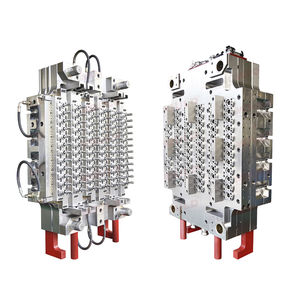

Multi-cavity plastic injection mold hot-runnerpackaginglarge series

Add to favorites

Compare this product

Characteristics

- Type of mold

- multi-cavity, hot-runner

- Cast parts

- packaging

- Operation

- large series, small series, medium series

- Applications

- for the packaging industry

- Certifications

- ISO 9001

Description

SINO Package has accumulated rich experience in various flip top cap molds from 1 cavity to 72 cavities, like shampoo flip top cap mold, lubricant oil flip top cap mold, condiment flip top cap mold, double safety ring flip top cap mold etc.

See how we customize one high quality flip top cap mold and what our flip top cap mold advantages are.

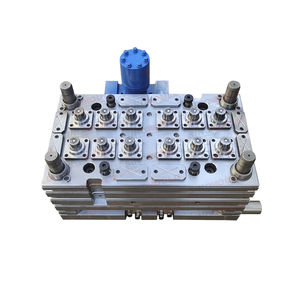

1. Pay high attention on the butterfly hinge design to make sure it is flexible and not easy break.

2. We adopt Moldflow analysis to imitate the whole injection process to guarantee inject qualified products during mass production.

3. High performance hot runner system with German heating parts to make sure uniform melt flow and pressure in all cavities.

4. Each cavity heat controlled independently to ensure the temperature is uniform.

5. Standard interchangeable mold components.

6. All the parts are tooled by high precision CNC equipment, the tolerances under 0.02mm.

7. Mold core and cavity by using high hardness steel and do anti-corrosion to double make sure high precision and long mold life.

8. Each cavity and core have independent cooling system, which can shorten the production cycle time.

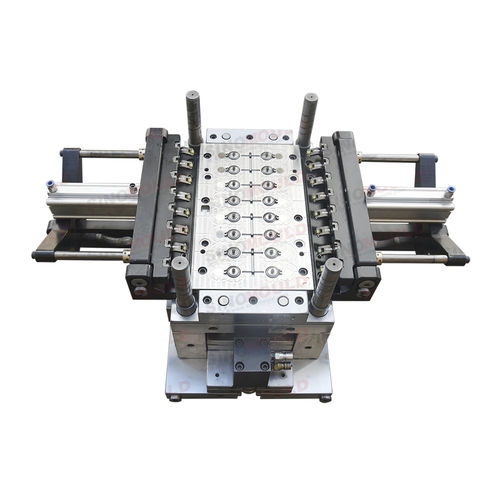

9. Special water hoses design eliminates leakage and water marks on preform.

10. Cavity can be changed convenient to change company logo of the caps.

11. Mold spares can be DME, HASCO or other standards, easy for customers to find the replacing component in the market.

12. We can provide CMM inspect mold key parts, such as inserts, cavity and core.

13. In mold closing system can be designed based on customer's requirement.

14. Long mold guaranteed life with more than 5 million shots.

Other Sino Mould Co.,Ltd Huangyan Taizhou products

Package Mould

Related Searches

- Plastic injection mold

- Multi-cavity plastic injection mold

- Plastic injection mold for the packaging industry

- ISO 9001 plastic injection mold

- Hot-runner plastic injection mold

- Small series plastic injection mold

- Large series plastic injection mold

- Medium series plastic injection mold

- Packaging plastic injection mold

- Technical parts plastic injection mold

- Plastic injection mold for industrial applications

- Plastic injection mold for the automotive industry

- Aesthetic parts plastic injection mold

- Crate plastic injection mold

- IML plastic injection mold

- Preform plastic injection mold

- Covers plastic injection mold

- Plastic injection mold for the food industry

- Chair plastic injection mold

- Plastic injection mold for the furniture industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.