- Production Machines

- Plastics Processing

- Hot-runner plastic injection mold

- Sino Mould Co.,Ltd Huangyan Taizhou

- Products

- Catalogs

- News & Trends

- Exhibitions

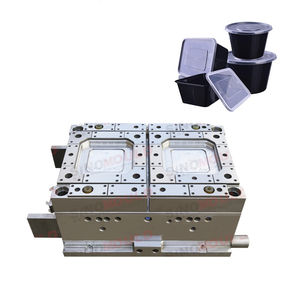

Multi-cavity plastic injection mold hot-runnerIMLpackaging

Add to favorites

Compare this product

Characteristics

- Type of mold

- multi-cavity, hot-runner, IML

- Cast parts

- packaging

- Operation

- large series, small series, medium series

- Applications

- for the packaging industry, for industrial applications, for the food industry, for the cosmetics industry

- Certifications

- ISO 9001

Description

Thinwall Food Container Mould

From 100ml upto 1500ml box mould, round box mould, thinwall IML molding box get high production capacity for profit.

To make thinwall food container, SINO design multi-cavity thinwall container in separate cavity molding inserts locking system, this not only saving the tooling period time, but also can avoid the tooling mistake risk for high precision tooling process.

With choosing high speed milling machine, valve gate system for fast flow of the raw material inside the cavity, effective cooling system for the mould temperature control and high speed moving of each step. Sino also offer IML molding system and robot automation for food container moulds.

Other Sino Mould Co.,Ltd Huangyan Taizhou products

Thinwall Container Mould

Related Searches

- Plastic injection mold

- Multi-cavity plastic injection mold

- Plastic injection mold for the packaging industry

- ISO 9001 plastic injection mold

- Hot-runner plastic injection mold

- Small series plastic injection mold

- Large series plastic injection mold

- Medium series plastic injection mold

- Packaging plastic injection mold

- Technical parts plastic injection mold

- Plastic injection mold for industrial applications

- Plastic injection mold for the automotive industry

- Aesthetic parts plastic injection mold

- Crate plastic injection mold

- IML plastic injection mold

- Preform plastic injection mold

- Covers plastic injection mold

- Plastic injection mold for the food industry

- Chair plastic injection mold

- Plastic injection mold for the furniture industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.