- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

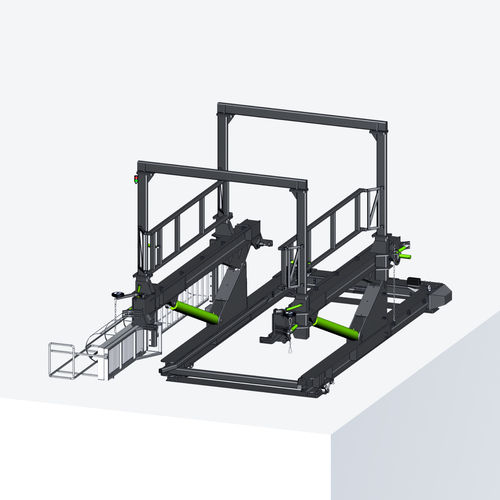

Container loading and unloading system CTfor truckstrailerbag

Add to favorites

Compare this product

Characteristics

- Product applications

- for containers, handling, for food products, for the pharmaceutical industry, trailer, bag, for the food industry, for woodworking, for trucks, accessibility, for storage systems, for the food and beverage industry, for warehouse, machine, for automatic storage systems

- Other characteristics

- automatic, hydraulic

Description

The SmartTEH Container Tilter is designed for efficient bulk material handling. It enables quick filling using gravity, tilting containers from -5° to 90° for full internal volume access. Containers can be inserted via forklifts, cranes, or reach stackers. Key features include streamlined bulk handling in less than five minutes, labor and equipment savings with customizable tilting options and frames, compact design, and robust construction. Optional extras include a digital scale system, remote control, mobile drive system, power pack options, hydraulic container door closer, and PLC plant integration. It's especially useful in agriculture, chemicals & pharmaceuticals, food, minerals, plastics, and recycling industries.

HOW IT WORKS:

1. Truck driver unlocks trailer pins; CT operator begins work.

2. Operator uses hydraulics to align pins with container holes on one side

3. Once one side is secure, the operator repeats the process for the other side and lifts the container off the trailer.

4. After the trailer has gone, the operator opens the door of the container and the container can be lifted vertically.

5. All operations are done in opposite sequences after loading or unloading.

SPECIFICATIONS:

- Max Load Size: Suitable for a 20ft container (including high cube).

- System Dimensions: Length 9845mm, Width 48406mm, Height 4781mm.

- Max Payload Weight: 28,000 kg.

- Productivity: 4 cycles per hour, dependent on the loading process and operator efficiency.

- Elevation Angle: -5° to 90°.

- Control: Manual.

- Unit Mass: Approximately 10 tons, varies with additional configurations.

- Electrical Connection: 400V, 63A, 3 phase.

- Working Temperature Range: -20 to +30 °C.

VIDEO

Catalogs

Container Tilting Equipment

14 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.