- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

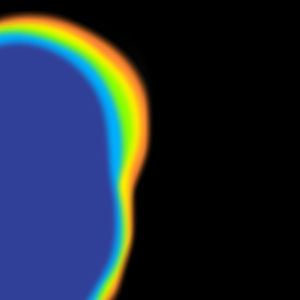

Heat mapping coating application system Instascan

Add to favorites

Compare this product

Characteristics

- Options

- heat mapping

Description

INSTASCAN COATING SYSTEM

Non-destructive Testing / Thermal Mapping

Instascan Coating System is a two-part coating system that will change color with changes in surface temperature originally developed for Non-Destructive Testing (NDT) of large area composite, laminated, and honeycomb structures.

Surface and Sub-Surface Flaw Detection in Metals, Welded Metals, Bonded and Other Composite Structures

Thermal Gradient Visualization of Temperature Fields

Aerospace and Engineering Research

Heat Transfer Studies

Electronic Component Testing

Simple Application; brushing, roller coating, spraying, or using hand or automated equipment

Instascan Black Base Coating

Instascan Black Base Coating is a black water-based pigmented coating designed for use as an undercoat to enhance adhesion and intensify the thermal response (color change properties) of the liquid crystal coat, which is applied over it. Application can be by brushing, roller-coating or spraying using hand or automated equipment. Ideally, the coating should be applied uniformly to completely cover the test surface. It can be thinned by adding distilled water and mixing well. Removal can be accomplished easily by washing with water and mild detergents.

Catalogs

No catalogs are available for this product.

See all of SpotSee‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.