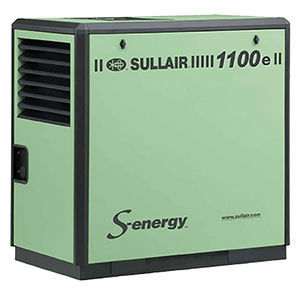

Rotary compressor TS-20airelectrically-poweredstationary

Add to favorites

Compare this product

Characteristics

- Technology

- rotary

- Type

- air

- Power source

- electrically-powered

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial, for food applications

- Applications

- for pharmaceutical applications

- Other characteristics

- heavy-duty, air-cooled, variable-speed, two-stage

- Pressure

Max.: 34.5 bar

(500.38 psi)Min.: 6.8 bar

(98.63 psi)- Flow

Max.: 84.9 m³/min

(2,998.22 ft³/min)Min.: 14.2 m³/min

(501.47 ft³/min)- Power

Max.: 447 kW

(607.75 hp)Min.: 112 kW

(152.28 hp)- Length

3,048 mm, 3,911 mm, 4,445 mm

(120 in, 154 in, 175 in)- Width

1,828 mm, 1,981 mm, 2,134 mm

(72 in, 78 in, 84 in)- Height

1,727 mm, 2,184 mm, 2,337 mm

(68 in, 86 in, 92 in)- Weight

3,334 kg, 5,770 kg, 7,212 kg

(7,350.2 lb, 12,720.7 lb, 15,899.7 lb)

Description

Sullair Two-Stage Air Compressors feature a superior end-to-end design for optimum efficiency and power savings.

Longer air end life

No loss of capacity or efficiency

Lower operating costs

Two-Stage Standard Pressure Models

Multi-Stage Air-Fluid Separation

Dual nested Optimizer™ separator elements, reduce fluid carryover to a maximum of 1 ppm

Reduced carryover lowers make-up fluid costs

Pleated Optimizer elements lower initial pressure drop for greater efficiency and extends element life

Easy to change with built-in lid lifting device

Fiberglass Fluid Filter

Aircraft-quality media provides better filtration

Up to 20% more efficient than conventional paper elements

Lengthens life of the compressor

Optimalair® Heavy-Duty Air Intake Filter

Includes remote air intake connection

Provides finest inlet filtration in the industry (99.95%+ overall efficiency/0.4 micron)

Keeps fluid clean and extends life of other internal components

Reduces pressure drop throughout the operating life, resulting in energy savings

Two-Stage Compressor Air End

Delivers more air

Reduces power consumption

Extends air end bearing life

Enhanced Serviceability for Air-Cooled Oil Cooler and Aftercoolers

Easy to remove panels provide access for cleaning coolers

Motor Coupled to Air End Through Non-Lubricated, Flexible Coupling

Allows use of standard NEMA frame motor

Simplifies installation and start-up

Variable Capacity Control System Featuring Spiral Valve Technology

Lowers part-load operating costs

Catalogs

SULLAIR Two-stage

12 Pages

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Oil-injected compressor

- Dry compressor

- Screw compressor

- Compact compressor

- Mobile compressor

- Cooled compressor

- Tank-mounted compressor

- Multi-stage compressor

- High-efficiency compressor

- Air-cooled compressor

- High-pressure compressor

- Two-stage compressor

- Rugged compressor

- Direct-drive compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.