- Production Machines

- Cutting Machine

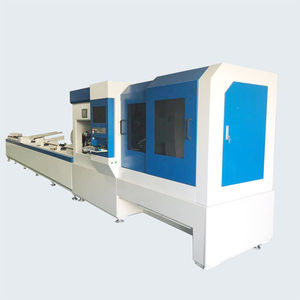

- Fiber laser cutting machine

- SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD.

Fiber laser cutting machine for metalfor glasstube

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal, for glass

- Product handled

- tube

- Control type

- CNC

- Applications

- for industrial applications, for the electronics industry

- Other characteristics

- high-speed, precision

- Tube diameter

1 mm

(0 in)

Description

A precision laser cutting system for automated processing of thin and thick metals and alloys, plus brittle materials like sapphire, PCD, and ceramics.

Application range

◆ Micromachining of metal stent materials

◆ Micromachining metal thin-walled tubular materials

◆ Cutting thin steel sheets with direct clamping

◆ Cutting stretched stencil

◆ Cutting other thin sheets

Specifications precision tube cutting

From Ø0,6mm

Scratch, burr-free

Both prototypes and large series

Large variety of materials

Except: high reflective materials (for example pure copper)

Cleaning of different materials

Several cleaning methods are available to finish laser cut tube components. Different materials demand different finishing approaches. A common used finishing method is ultrasonic cleaning using a chemical solution.

Tube material on stock, supplied by the customer or custom made

If necessary, tube material can be made to measure by external suppliers. This way, tube components can be created with the exact, required dimensions in terms of inner and outer diameter, wall thickness, surface roughness, material properties, tensile strength, …

Laser wavelengths for thin metal cutting applications range from UV to NIR. High-speed fiber lasers (1064 nm) melt and ablate the metal quickly, while diode-pumped solid-state (DPSS) lasers work well for applications requiring higher precision.

In addition, UV lasers achieve precise, detailed cuts, minimal kerf widths and low heat-affected zones. You can also use UV lasers if your application requires a clean cut edge. Finally, ultrafast femtosecond and picosecond lasers achieve the best cut quality and are used to cut metals and coated metals.

VIDEO

Other SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD. products

Metal Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- High-performance cutting system

- Cutting machine for the automotive industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.