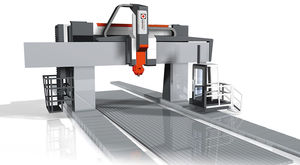

4-axis CNC machining center FRP series verticalwith fixed portalfor the aeronautical industry

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- vertical

- Structure

- with fixed portal

- Applications

- for the aeronautical industry

- Other characteristics

- high-precision, high-speed, with linear motor, hydrostatic

- X travel

3,000 mm, 4,000 mm, 5,000 mm, 5,500 mm, 13,500 mm

(118 in, 157 in, 197 in, 217 in, 531 in)- Y travel

Min.: 2,900 mm

(114 in)Max.: 6,800 mm

(268 in)- Z travel

1,250 mm, 1,500 mm, 2,000 mm

(49 in, 59 in, 79 in)- Power

30 kW, 37 kW, 45 kW, 60 kW, 71 kW

(40.79 hp, 50.31 hp, 61.18 hp, 81.58 hp, 96.53 hp)- Work feed X-axis

Min.: 1 mm/min

(0 in/s)Max.: 30,000 mm/min

(20 in/s)- Work feed Y-axis

Min.: 1 mm/min

(0 in/s)Max.: 30,000 mm/min

(20 in/s)- Work feed Z-axis

Min.: 1 mm/min

(0 in/s)Max.: 30,000 mm/min

(20 in/s)

Description

The FRP gantry centre is designed for standard or high-speed machining of large and very complex workpieces. It consists of a bed on which the table is shifted and a fixed gantry with a movable cross-rail. Customers can choose between a linear and hydrostatic guideway.

FRP also allows turning, which is possible thanks to an optional VTL table. The machine is equipped with versatile spindle heads, which allow a variety of machining operations. The customers choose it for machining aircraft engines, locomotive diesel engines or steam turbine casings. Thanks to its high performance and torque, FRP can also be used for roughing operations.

Catalogs

No catalogs are available for this product.

See all of TOS KURIM‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- High-productivity CNC machining center

- Horizontal CNC machining center

- High-rigidity turning center

- High-performance turning center

- Vertical turning center

- High-productivity turning center

- 4-axis CNC machining center

- High-speed CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.