- Production Machines

- Forming Machine

- Servo-electric bending machine

- Pipe Bending Systems GmbH & Co.KG

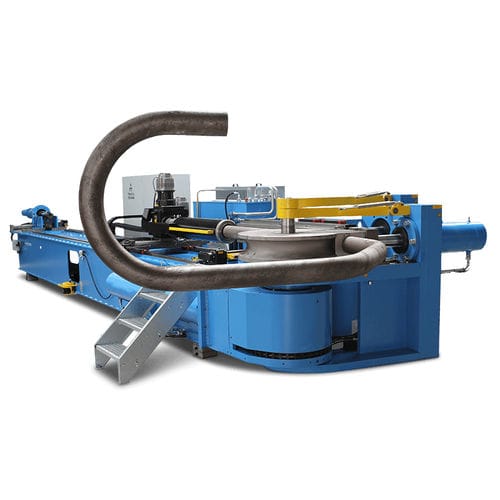

Hydraulic bending machine TUBOTRON 170 (HD)electricservo-electrictube

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, electric, servo-electric

- Product handled

- tube

- Control

- CNC, automatic

- Other characteristics

- mandrel, precision, mobile

- Bending capacity

Max.: 170 mm

(7 in)Min.: 0 mm

(0 in)- Bending radius

Max.: 510 mm

(20.08 in)Min.: 0 mm

(0 in)- Bending length

Max.: 6,000 mm

(236 in)Min.: 4,500 mm

(177 in)- Weight

16,000 kg

(35,274 lb)- Total power

43 kW

(58.5 hp)

Description

CNC-PIPE BENDING MACHINE

FULLY AUTOMATIC AND POWERFUL!

The CNC pipe bending machines of the TUBOTRON series fulfill the highest quality demands regarding design, performance and fabrication. They are perfectly suited for series production as well as for flexible single production of pipe bending parts.

CNC PIPE BENDING MACHINE

DISCOVER THE

TUBOTRON PIPE BENDING MACHINE

By using the most advanced control techniques even complex pipe shapes can be bent at minimum cycle times and highest precision. The bending machines are operated via SIMATIC Panel PC or SIMATIC Operator Panel. An interface for remote maintenance of the machine control is standard.

Basic equipment and features

Programmable sequence control with menu-driven user guidance via SIMATIC Touch PC

on mobile control board

Hydraulic bending drive

Hydraulic pipe clamping (power and distance programmable)

Hydraulic pressure die positioning (power and distance programmable)

Follower-type pressure die (linear guiding)

Pressure die assist (power programmable)

Servo-electric pipe feed and rotation

Hydraulic long-neck collet chuck allows for positioning of the pipe in the pressure die area,

with pipe re-gripping functionality

Foot switch for hydraulic collet chuck

Hydraulic and anticipated mandrel retraction

Programmable servo-electric radius adjustment of the pipe positioning device and

the mandrel retraction system

Automatic minimum quantity mandrel lubrication

Pipe and mandrel support

Interface for remote maintenance of the machine control

Oil cooler

Quick-change system for the bending tools

Catalogs

TUBOTRON 170 (HD)

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Other Pipe Bending Systems GmbH & Co.KG products

TUBOTRON

Related Searches

- Bender

- Tube bender

- Hydraulic bender

- Electric bender

- CNC bender

- Automatic bender

- Forming machine

- Horizontal bending machine

- Manual bender

- Precision bender

- Mandrel bender

- Metal forming machine

- Vertical bending machine

- Electro-hydraulic bender

- Digital bending machine

- Compact bender

- Cutting bending machine

- Hydraulic forming machine

- Pipe-end forming machine

- Mobile bending unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.