- Metrology - Laboratory

- Metrology and Test Equipment

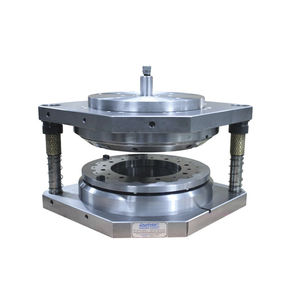

- Leakage tester

- Umar Makina Company

Electric tester MAC/08721leakagepressurefor metal sheets

Add to favorites

Compare this product

Characteristics

- Test type

- electric, leakage, pressure

- Tested product

- for metal sheets

- Applications

- industrial, for production

- Other characteristics

- analog, pneumatic

Description

Perfectly synchronizes with Body Assembly Lines to examine leakage on cans.

Cans are fed by a conveyor to the machine and pneumatic stoppers are holding the cans on the conveyor.

A star which is rotating synchronized with the main rotary heads of the tester is taking the cans one by one and placing them under one of the eighteen testing heads. Upper tampon is pressed down pneumatically to the filing hole for hermetic seal. Vacuum pump sucks the air up to the set point and a special valve closes the line.

Analog vacuum gauge is following the pressure range and if the pressure is under set range,the can is ejected while passingthe exit conveyor.

Inline machine

Testing principle: By vacuum (supply by electrical vacuum pump)

Testing of can with filling hole on the corner, on center or top full open cans.

With protection cabin

Easy and User friendly HMI

Testing machine for smaller size round and square cans and faster machines available

Capacity - 50 cans/min

Testing Stations - 18 heads

Testing Time - 15 second (approximate)

Body Height Range - 250 – 400 mm

Min. Body Dimensions - 190 x 190 mm

Max. Body Dimensions - 235 x 235 mm

Total Electric Power - 2.3 kW

Air Consumption - 30 Lt / minute (at 5 bar)

Catalogs

No catalogs are available for this product.

See all of Umar Makina Company‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.