- Products

- Catalogs

- News & Trends

- Exhibitions

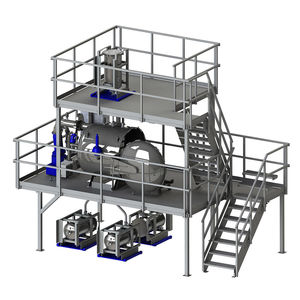

Centrifugal classifier AKMP seriespowder

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Separated substance

- powder

- Filtration size

Max.: 300 µm

Min.: 0 µm

Description

In the production of metal powders for additive manufacturing, the challenge is to remove the fine powder fractions of less than 10 µm from the target product. Classic screening machines are not able to screen out such small fractions. To solve this problem, Vilitek offers inert-gas air classifiers.

The screening of fine fractions occurs due to passage of particles’ flow with carrier gas through the rapidly rotating classifying rotor. Centrifugal force and carrier gas move in opposite directions in the classifier. Thus, only particles with a little weight can pass through classifying rotor. The specific particle size corresponding to cut point is set in control system for changing the classifying rotor speed, carrier gas speed and secondary gas flow in the classifier.

Unlike classifiers from other manufacturers, the Vilitek AKMP classifiers are sealed. Units with rotational inputs are equipped with magnetic couplings or are in sealed capsules. Due to such design, Vilitek AKPM classifiers are excellent for working in both nitrogen and argon. Powders are supplied from Vilitek BATT tanks, the classified powder is also collected in standard tanks of this series.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.