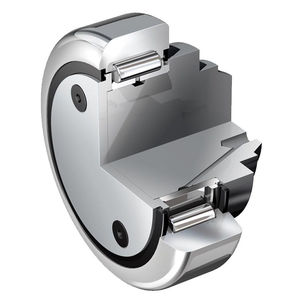

Axial bearing unit JT-V seriesradialcylindrical rollerhardened steel

Add to favorites

Compare this product

Characteristics

- Type

- radial, axial

- Rolling element

- cylindrical roller

- Material

- hardened steel

- Other characteristics

- lubricated, economical

Description

-Clearance radial and axial steplessly adjustable by thread bolts

-Higher radial and axial précision

-Higher dirt résistance

-Travel speed up to 16 ft/sec

Advantage of the WINKEL Bearing system:

-Reduces your designing and production costs

-Can take up high radial and axial loads

-Strong profiles for high stat. and dynamic loads

-Best dispersion of forces in the profiles

-Longer lifetime for bearings and profiles

-Economical assembling by welding bolt

-Bearing components are easily exchangeable

Technical details:

-Outer rings are made from case-hardened steel UNI 16 CrNi 4 hardened at 62+2HRC

-Inner rings are made from bearing steel En 31-SAE 52100 hardened at 62-2 HRC

-Cylindrical rollers have flat ground heads, made from En 31-SAE 52100 steel hardened at 59 – 64 HRC

-Welding bolts are made from C22E (Material no. 1.1151)

-Bolt tolerance –0.05 mm

-Bearings from 4.054 to 4.063 are relubricateable

-Bearings are lubricated with grease grade 3 (e.g. Shell Gadus S2 V100 3)

-Standard WINKEL Bearings are resistant from -20 °C to +80 °C

-WINKEL High Temperature Bearings can be used at max. +250 °C environmental temperature.

-The max. speed for WINKEL Bearings in steel version is 3m/s.

-For VULKOLLAN® and POLYAMIDE kind of bearings is the max. speed 6 m/s.

-The clearance between axial bearing and inner side of the profile should not exceed 0,5 mm.

Catalogs

WINKEL Catalogue

420 Pages

Related Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Linear motion system

- Axial rolling bearing

- Bearing unit

- Precision bearing

- Cylindrical roller rolling bearing

- Slide linear motion system

- Metal bearing unit

- High-speed bearing

- Track linear motion system

- Stainless steel rolling bearing

- Sealed bearing

- Heavy load bearing

- Combined bearing

- Large bearing

- High-temperature bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.