- Machine-tools

- Machining Center

- 3-axis machining center

- YCM (Yeong Chin)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

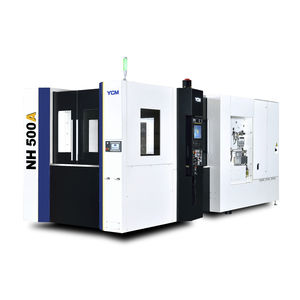

3-axis CNC machining center NH630Bhorizontaldouble-columnwith rotary table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Structure

- double-column, with rotary table

- Spindle mount

- CAT50

- Number of tool stations

- 40 tools, 60 tools, 120 tools

- Applications

- cutting, for automatic tool changers

- Other characteristics

- high-speed, high-performance, high-precision, high-rigidity, with pallet changer

- X travel

1,050 mm

(41 in)- Y travel

850 mm

(33 in)- Z travel

850 mm

(33 in)- Rotational speed

8,000 rpm, 10,000 rpm

(50,265 rad.min-1, 62,832 rad.min-1)- Power

45 kW, 55 kW

(61.18 hp, 74.78 hp)- Work feed X-axis

40,000 mm/min, 60,000 mm/min

(26 in/s, 39 in/s)- Work feed Y-axis

40,000 mm/min, 60,000 mm/min

(26 in/s, 39 in/s)- Work feed Z-axis

40,000 mm/min, 60,000 mm/min

(26 in/s, 39 in/s)- Table load capacity

1,200 kg

(2,646 lb)- Tool weight (max)

25 kg

(55.1 lb)- Weight

Max.: 25,000 kg

(55,115.57 lb)Min.: 24,000 kg

(52,910.94 lb)

Description

Stepped castings design on X-axis to increase the cutting rigidity.

Dual-wall column design for eliminating possible thermal deformation.

High Rigidity Roller Guideways

Oversize roller guideways increase rigidity and precision.

High dynamic AC servo driven pre-tensioned ball screws, delivering high control qualities.

60 m/min. rapid feedrate increase machining efficiency.

Y-axis Dual Drive System

Headstock is driven at the center of the gravity to minimize vibration. The dual-driven design restrains vibration and delivers high speed, high quality machining ability while increasing machine performance and tool life.

Built-in motorized spindle reduces vibration during high-speed machining and ensures spindle life.

Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life.

Circulated oil jacket cooling system minimizes thermal deformation, ensuring high accuracy.

High Capacity Machining Space

ø1,100 mm x 1,000 mm largest working envelope within its rank.

12-second pallet change.

Servo motor driven.

Simple structural design, fast reliable movement and easy maintenance.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Turning center with turret

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.