- Machine-tools

- Machining Center

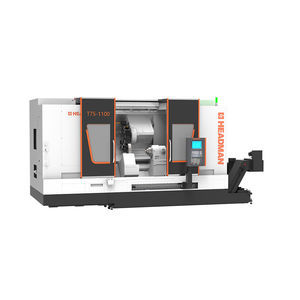

- CNC lathe

- ZHEJIANG HEADMAN MACHINERY CO., LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC lathe T50-300A2-6belt drivespindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Spindle orientation

- horizontal

- Spindle mount

- A2-6

- Drive system

- belt drive

- Other characteristics

- high-precision, high-rigidity, spindle

- Diameter

550 mm

(21.65 in)- Spindle speed

5,000 rpm

(31,415.927 rad.min-1)- Part diameter

330 mm

(13 in)- Maximum part length

280 mm

(11 in)- Axe X

190 mm

(7 in)- Axe Z

330 mm

(13 in)- Rapids on X

28,000 mm/min

(18 in/s)- Rapids on Z

33,000 mm/min

(22 in/s)- Overall lenght

2,063 mm

(81 in)- Overall width

1,780 mm

(70 in)- Overall height

1,880 mm

(74 in)- Weight

3,300 kg

(7,275 lb)

Description

High precision and high rigidity spindle structure

• High precision double-side dynamic balance struture

• Quantification measurement of preload

• Spindle thermal equilibrium experiment

• Dynamic precision test

High precision & rigidity servo hydraulic turret

• It adopts the basic structure with servo motor indexing, arc gear tooth positioning, hydraulic locking.

• Turret index without lifting, reduce the tool change movement, avoid scraps & coolant entering inside of the turret to influence the positioning accuracy.

• The toothed disk is tightly locked by hydraulic force to ensure that the 7Mpa high pressure cooling water still maintains enough tension when passing through the turret.

CNC system

High speed and high precision control

It adopts GSKLink industrial Ethernet bus technology. The highest running speed is 100m/min. Gr-l series servo devices and servo motors with high resolution absolute encoders are standard equipped, which can be connected with grating scale, reluctance, magnetic grid, circular grating encoders, etc., to realize full closed-loop control of feeding axis and high-

Simple and fast system debugging guide

This function can list the parameters to be debugged according to the debugging steps, functional modules and other projects, so as to simplify the debugging process of machine tools.

Examine intelligently/Diagnosis technology

It has the functions, including grammar check, track preview, machine tool fault diagnosis, as well as operation log, alarm log and machining log, which are convenient for program verification, fault diagnosis and maintenance.

Other ZHEJIANG HEADMAN MACHINERY CO., LTD. products

T Series - turret

Related Searches

- Turning center

- CNC turning center

- High-precision turning center

- 12 tools turning center

- Spindle lathe

- High-rigidity turning center

- Vertical turning center

- Powerful turning center

- Milling turning center

- Compact turning center

- Cutting turning center

- Drilling turning center

- A2-6 turning center

- A2-8 turning center

- 4-axis turning center

- A2-5 turning center

- Grinding turning center

- Boring turning center

- Belt drive turning center

- 4 tools turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.