- Environment - Health - Safety

- Waste Treatment

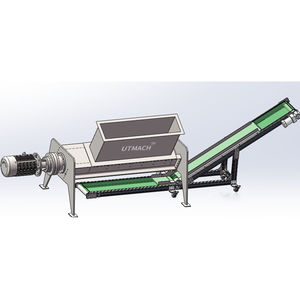

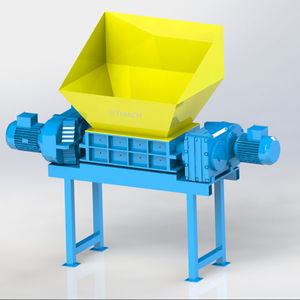

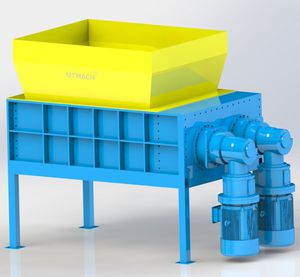

- Single-shaft shredder

- Zibo United Tech Machinery Co., Ltd.

Single-shaft shredder S Seriesfor woodfor cardboardfor cables

Add to favorites

Compare this product

Characteristics

- Number of shafts

- single-shaft

- Application

- for wood, for cardboard, for cables, for non-ferrous materials, tire, paper, for waste

- Other characteristics

- high-torque, rotary shear, for high torque, reinforced

- Power

Min.: 18,500 W

Max.: 180,000 W

- Output

Min.: 100 kg/h

(220 lb/h)Max.: 10,000 kg/h

(22,046 lb/h)- Rotor diameter

Min.: 220 mm

(9 in)Max.: 500 mm

(20 in)- Rotational speed

Min.: 50 rpm

(314 rad.min-1)Max.: 100 rpm

(628 rad.min-1)- Operating weight

Min.: 2,000 kg

(4,409.2 lb)Max.: 14,000 kg

(30,864.7 lb)- Machine Length

Min.: 2 m

(6'06" )Max.: 4 m

(13'01" )- Machine Width

Min.: 1 m

(3'03" )Max.: 5 m

(16'04" )- Machine Height

Min.: 2 m

(6'06" )Max.: 3 m

(9'10" )

Description

S Series Single Shaft Shredders from Zibo United Tech Machinery Co., Ltd. are versatile size reduction machines suitable for processing a wide range of materials to a uniform particle size.

Single shaft shredder is available to recycle wide range of material. It is an ideal machine for plastic, paper, wood, fiber, rubber, organic waste a wide variety of non-metallic materials.As per our customer’s requirements, such as the input size of materials. Capacity and the final output size etc. We could work out a suitable proposal for our clients. After being shredder by the machine, the output material could be used directly or go int to the next step of size reduction.

Single Shaft Shredder Advantages:

* Detachable rotor blade, easy disassemble and installation, and simple maintenance.

* Automatic feeder, increase produce efficiency.

* Quick change screen for accurate particle size control.

* Shock absorbing gearbox reduces stress on drive components.

* Integrated rotor, assured the cutter clearance between the rotor blade and the counter blade.

* Enclosed bearing protection design, waterproof and dustproof, extend the bearing work life.

* PLC control system, automatic reverse sensor to protect the machine against over loading and jamming.

* Provide the rotor cooler system against the low melting materials, prevent the materials burning while the temperature higher.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other Zibo United Tech Machinery Co., Ltd. products

Shredder

Related Searches

- Grinding mill

- Crushing plant

- Solid classifier

- Stationary crushing and screening plant

- Liquids separator

- Waste shredding machine

- Baling press

- Horizontal grinding mill

- Eddy current separator

- Pelletizer

- Vertical grinding mill

- Single-shaft shredding machine

- Impact crushing and screening plant

- Primary shredding machine

- Wood shredding machine

- Jaw crushing and screening plant

- Two-shaft shredder

- Recycling plant

- Vertical chamber baling press

- Rotor lump breaker

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.