- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Optical profilometer ZeGage™ Pro3Dwhite light interferometryinterferometry

Add to favorites

Compare this product

Characteristics

- Technology

- optical, 3D, white light interferometry, interferometry

- Function

- roughness, flatness

- Applications

- industrial, laboratory, for production lines

- Configuration

- benchtop

- Other characteristics

- non-contact, non-destructive

Description

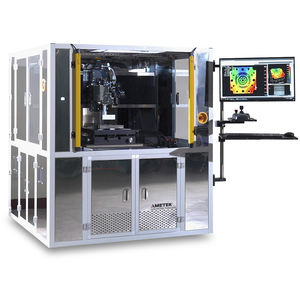

Production Ready 3D Optical Profiler System

ZeGage Pro HR 3D Optical Profiler

The ZeGage™ Pro and ZeGage™ Pro HR 3D optical profilers provide non-contact measurement and characterization of micro- and nano-scale features of many types of surfaces, ensuring quality control and process monitoring in your manufacturing environment.

Our industry-leading ZeGage Pro-series sets the standard for performance, ease of use, flexibility, and precision of benchtop-class industrial non-contact surface profilers. Built on ZYGO’s proprietary CSI technology, the ZeGage Pro delivers innovative technologies to enable precise, reliable, simple, and confident surface metrology.

Exclusive capabilities include SureScan™ technology for vibration robust metrology, Part Finder, and Smart Setup for simplified part setup and optimized measurements. It’s never been simpler to measure a wide variety of surfaces and parts, quickly and easily.

Read more to see how the ZeGage™ Pro systems' power, versatility, and value can benefit you.

• Proprietary non-contact measurement technology is enhanced with SureScan™ technology for low sensitivity to vibration and easy placement anywhere within your facility.

• Quantitative surface metrology with nanometer-level precision provides superior gage capability.

• High resolution 1.9 million pixel image sensor provides fast areal measurements in seconds, for excellent surface detail and visualization.

• Fully-automated measurement sequences and field stitching enable high resolution inspection of large areas. (Requires optional motorized part stage.)

VIDEO

Catalogs

Zygo 3D Optical Profilers

24 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.