- Production Machines >

- Other Manufacturing Equipment >

- Granulator >

- Hosokawa

Hosokawa granulators

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Final grain size: 100 µm - 20,000 µm

The Brabender Pelletizer offers a low-noise operation, and features an adjustable floor for various bag and container sizes. It can can pelletize up to 4 strands of 4 mm in diameter, with pellet length up to 3 mm, and ...

Capacity: 130 kg/h

Motor power: 6 kW

The new generation of ultra-compact granulators, SINCRO EKO, for the recycling of copper and aluminum cables, available in four different models with a production capacity range from 50 to 400 kg/h, input. The evolution ...

Guidetti Recycling Systems

Capacity: 130 kg/h - 180 kg/h

Motor power: 20 kW

The new compact granulators of the series SINCRO MILL allow to process simultaneously rigid copper cables and very thin ones, without the necessity of pre-selection and they are easy to maintain as ever. Despite the compactness ...

Guidetti Recycling Systems

Capacity: 65 kg/h

Motor power: 4 kW

The new generation of ultra-compact granulators, SINCRO EKO, for the recycling of copper and aluminum cables, available in four different models with a production capacity range from 50 to 400 kg/h, input. The evolution ...

Guidetti Recycling Systems

underwater pelletizing systemJWT series

PET Bottle flakes recycling high quality pelletizing line This series of production unit is mainly suitable for PET bottle slice and waste silk granulation. The screw is made of LTM low-temperature mixing elements, the screw is nitrided ...

PET bottle flakes sheet recycling twin screw extruder pelletizing machine PET bottle flakes in the process of recycling has strict requirements to the viscosity of the granules, through years of hard search, steady accumulation, our ...

... force. G-Max granulators combine energy saving, a compact footprint and a unique damped cutting chamber for significant noise reduction, ensuring a quiet and efficient operation. The G-Max 9 hopper comes in 3 different ...

WITTMANN

Motor power: 30,000, 18,500, 22,000, 7,500, 11,000 W

Final grain size: 6 mm

... required. In addition to its reduced footprint and weight, the ZERMA GST Granulator retains all the features that have made it a favorite among industry professionals. The granulator continues to deliver ...

ZERMA Europe GmbH & Co. KG

ZERMA Europe GmbH & Co. KG

Capacity: 50 kg/h - 500 kg/h

Motor power: 7,500, 11,000, 18,500 W

Final grain size: 6 mm

... Applications The GSL slow speed granulators of the 300 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. But they can be used as low noise central ...

ZERMA Europe GmbH & Co. KG

Capacity: 1 kg/h - 3,500 kg/h

Final grain size: 1 mm - 5 mm

EUP Pelletizer ECON is the leading provider of underwater pelletizing technology with thermally insulated die plates. The die plate is fixed on the heated carrier body. The thermal insulation ensures that the melt ...

ECON GmbH

Capacity: 1 kg/h - 3,500 kg/h

Final grain size: 1 mm - 5 mm

ECONia combines the advantages of thermal insulation and Industry 4.0 in an innovative, new way. An integrated robot (aiCON) takes over the usual operating processes, making a fully automated line become reality. The manual start-up process ...

ECON GmbH

Capacity: 1 kg/h - 30 kg/h

Final grain size: 1 mm - 5 mm

The ECON air pelletizer was especially developed for processing wood and natural fiber compounds (such as WPC). An underwater pelletizing system requires a substantial amount of drying, as water is ...

ECON GmbH

Extrusion lines for the production of GRANULES Bausano produces extrusion lines suitable for production of granules for subsequent moulding, extrusion or calendering, starting from virgin or recycled material. These lines are fully customisable ...

Bausano & Figli S.p.A.

Die heads or pelletizing units are used in strand pelletizing systems for extrusion of granules. Bausano granulation heads are used for the production of thermoplastic granules, both virgin and recycled, obtained from ...

Bausano & Figli S.p.A.

The frontal air cutting unit is a cutter with non coaxial cutting blades in relation to the granulation head. This construction feature allows the blade surface temperature to remain low, preventing the decomposition of any processed ...

Bausano & Figli S.p.A.

Capacity: 500, 2,500 kg/h

... throughputs, and its simple handling and easy operation make it an excellent and robust pelletizer at an economical price. The BKG® Type A underwater pelletizer with manual blade pressure regulation ...

Nordson Polymer Processing Systems

Capacity: 500, 1,200, 2,000 kg/h

Motor power: 9, 18 kW

The BKG® Master-Line™ is our entry-level tempered water system with everything you need and nothing you don‘t. Cost-effectively produce high-quality pellets and benefit from various options to suit your process perfectly. Efficient ...

Nordson Polymer Processing Systems

Capacity: 5,000, 7,500, 11,500 kg/h

The highly automized BKG® Type AH D pelletizers for large throughputs provide cutting technology at its best. The precise, reproducible, and constant blade pressure actuation ensure a high-quality pellet, even for complex ...

Nordson Polymer Processing Systems

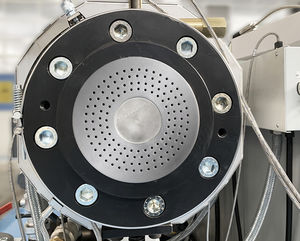

Using a tangential fluid bed system represents state of the art technology in pharmaceutical manufacturing for particle coating, granulation and drying. With the innovative and patented Bohle Uni Cone BUC ® process a complete fluidization ...

L.B. Bohle Maschinen und Verfahren GmbH

In the roller compactor powders are processed into fluid granules. The objective in the pharmaceutical industry is to process a granule with defined density or porosity for immediate tabeletting thereafter. The powder is fed via a dosing ...

L.B. Bohle Maschinen und Verfahren GmbH

Bohle Compact Unit - Small footprint, high quality The individual components of the High Shear Granulator GMA, wet sieve BTS, Fluid Bed System BFS and Bohle Uni Cone BUC ®, cyclone separator and dry sieve BTS are optimally ...

L.B. Bohle Maschinen und Verfahren GmbH

Motor power: 1.5 kW

The EPS granulator EG is designed for granulating EPS material and reduce volume in ration 3:1. Suitable for industrial companies and retail stores with bulky EPS waste material. The granulator reduces ...

twin-screw pelletizing systemPOY-60TPD

Background China has banned importing waste PET from 2018. It will have a significant impact on RPET industry in the world. BoReTech believe that renewable resource applications by indigenization is the most environmentally friendly ...

By adding one or two Hytherm retentioners to your pelleting system you can enhance feed safety with retention times of 30 to 240 seconds. The "first in, first out" principle ensures a uniform thermal treatment for all of your particles.

Capacity: 50 kg/h - 25,000 kg/h

Underwater pelletizing system is good for most of polymers. Especially for TPU and TPV or similar elastomer, its advantage plays well. USEON can provide complete compounds production lines with underwater pelletizing ...

USEON Technology Limited

Capacity: 250 kg/h

Motor power: 1, 2, 3 kW

Final grain size: 4 mm

... maintenance. The threshold of operators is also low. This system consists of strand die, water batch, air knife, strand pelletizer and vibrating classifier. - Fast open type die plate Material: 38CrMoAlA with ...

USEON Technology Limited

Capacity: 900 kg/h - 1,000 kg/h

This system is suitable for plastic recycling which needs to change the filter frequently. The strands go into the pelletizer automatically by the water flow, even the strands break during changing the filter. So there ...

USEON Technology Limited

Final grain size: 2 cm - 3 cm

The equipment is widely used in thermoplastic material processing fields such as elastomer, engineering plastics, biodegradable materials, masterbatch, recycled plastics, hot melt adhesives, etc. For example: PP, PP PS, PC, SAN, ABS, ...

Capacity: 100 kg/h - 400 kg/h

Motor power: 8, 11, 15, 22 kW

CE Certificated Description Benefits & Features •The device is applicable to centralized pulverizing of all kinds of plastics, including the waste of injection moulding, blow molding and extrusion forming. •The structure of ...

SANTSAI MACHINERY

Capacity: 15 kg/h - 80 kg/h

Motor power: 2.2, 1.5 kW

CE Certificated Description Benefits & Features •The device is applicable to crushing hard and thick materials and a small quantity of waste. Principle design of teeth cutters and staggered blades makes least dusts produced in ...

SANTSAI MACHINERY

Capacity: 100 kg/h - 1,200 kg/h

Motor power: 4 kW - 45 kW

CE Certificated Description Benefits & Features •The device is applicable to centralized pulverizing of all kinds of plastics, including the waste of injection moulding, blow molding and extrusion forming. •The structure of ...

SANTSAI MACHINERY

Motor power: 55, 90 kW

G series strong Granulator from United Tech is designed to meet high production fragmentation and large item broken at once production needs heavy recovery equipment. Its mainly used for broken plastic, rubber and metal ...

Zibo United Tech Machinery Co., Ltd.

Motor power: 2, 4 kW

This series of plastic shredder is slow speed crushing, and can control the output size. It is suitable to the plastic material crushing. Features: Low speed rotate, high torque, less dust, simple operation, low electricity consumption, ...

Zibo United Tech Machinery Co., Ltd.

Capacity: 20 kg/h - 80 kg/h

Motor power: 3, 5 ch

1.The high chromium tool steel blade is cut resistant and wear-resisting, the rotating blade can flip for twice life time. 2.The bearing house designed with screw sealing plate, and two holes on cover,it's convenient for air clean. 3. ...

Zibo United Tech Machinery Co., Ltd.

Capacity: 0.5 t/h - 8 t/h

Excellent granular fertilizers with the new type organic fertilizer granulating machine! With the organic fertilizer granulator machine (GENEMA-GGM Series), it is now very easy to produce high-strength granular organic ...

Motor power: 700, 2 W

• The XENA-II, Lab Scale High Shear Mixer has been designed to turn a fine-powder heterogeneous mixture into a uniform granulation, with increased particle size and higher density. • The high-shear wet granulation process is ...

Motor power: max 7.5 kVA

• The XENA-V FBS is the ideal solution for your lab-scale and R&D fluid bed processing requirements. • The Compact design improves work efficiency and reduces installation hassles. • Suitable for almost all fluid bed processes: Granulating, ...

... total volume will no longer be a challenge for you in the future. Get the ideal mixer-granulator for your start in production now. With the P100 mixer-granulator, you benefit from highly effective ...

DIOSNA Dierks & Söhne GmbH

Capacity: 100 kg/h - 150 kg/h

The BIG MACO separating granulator is manufactured in our workshops in France by specialists in the recycling of metals. The BIG MACO is easy to use and very robust. It has a crusher with 12 flying knives and 2 fixed ...

Copper-Rec

Capacity: 30 kg/h - 80 kg/h

Motor power: 3 kW

Final grain size: 2 mm

Granulator separator MINI MACO, the first granulator French 220 volts entirely manufactured in our workshops. The MINI MACO crushes and separates the copper from plastic. We know it is difficult to ...

Copper-Rec

Capacity: 30 kg/h - 50 kg/h

CRUSHER GRANULATOR SEPARATOR MINI MACO Granulator separator MINI MACO, the first granulator French 220 volts entirely manufactured in our workshops. The MINI MACO crushes and separates ...

Copper-Rec

The pelletizer GTE (300 mm diameter, 9.5 litre) is attached to the AR 403 via the Universal Gear UG which enables the operator to adjust the operating angle to the optimal position during operation. The material can ...

Wet Granulator with oscillating rotor for the production of wet granules. The granules can be produced in varying sizes depending on the employed sieve mesh. All parts coming into contact with the product are made ...

The machine has unique structure, big processing capacity and lower power consumption. With high separation rate, controlled by PLC system, the separation is conducted by each component coordinately. This equipment has not only improved ...

The MG 100 is a moist granulator engineered by Alexanderwerk. It is specifically designed for use in pharmaceutical or chemical industry, and also for natural resources. The granulator is constructed ...

Alexanderwerk

The MG 244 model, manufactured by Alexanderwerk, is a moist granulator specifically engineered for being capable of performing given a range of applications. This moist granulator is capable of operating ...

Alexanderwerk

The rotor fine granulator RFG 150 DA was designed by Alexanderwerk as a plug-on device on a universal drive motor for use in the chemical, pharmaceutical and food industries as well as life science and nuclear technology, ...

Alexanderwerk

... applications: •Extruders with a diameter of 18 - 60 mm •Cooling trays in different lengths, with an optional cooler. •Granulators ranging from 2 to 150 kg/h This equipment can also be used to extrude pipes or small profiles.

laboratory granulatorHMI

Application The pelletizer is used to directly granulate the extruded products after the conveyor / -cooling belt or the water bath. The speed of the strand feeding roll and the cutting knife can be adjusted seperatly. ...

Granulator ECO The granulator was built to directly granulate the extruded products after the water bath or the conveyor belt. The granulate length can be adjusted by means of different cutting knifes ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining