Website:

AViTEQ Vibrationstechnik GmbH

Website:

AViTEQ Vibrationstechnik GmbH

AViTEQ Vibrationstechnik GmbH

Who we are

About us

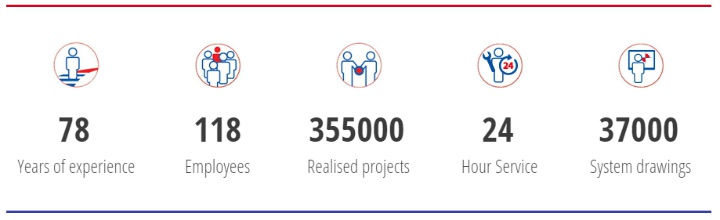

Drive components and vibration feeder plants based on vibration feeder technology form the core range of the spectrum of the in 1998 from AEG Vibrationstechnik GmbH renamed AViTEQ Vibrationstechnik GmbH since 1939.

Additionally, we offer comprehensive worldwide service for commissioned AViTEQ and AEG systems. We supply high-quality basic components for vibration feeder technology applications such as unbalanced motors, magnetic vibrators, appropriate controller systems and other drive systems.

Our competence for solving problems is based on the experience collected in 300.000 implemented units and applications worldwide.

AViTEQ-Vibration feeder technology guarantees maximum adaptability and the flexible design of conveying lines with highest safety and hygiene requirements.

Past until today

The history of AViTEQ Vibrationstechnik GmbH dates back to the year 1939. At that time as part of the conglomerate AEG, it is now in private property after the management buyout in the year 2006.

Our values

Perfection is never found on the shelf: IT DEVELOPS IN THE MIND

Conveying capacity, bulk density, grain size and product moisture, or necessary operations such as discharging, conveying, dosing, screening and cooling – each requires a specific design. Off-the-shelf solutions seldom provide maximum optimisation, which is exactly what you need to stand apart from your competition. That is why more than one-third of AViTEQ’s employees are involved in developing custom solutions that consistently improve systems and components. Highly specialised engineers from the development, construction and engineering departments work as a close-knit team. The intensive exchange of clever ideas, expertise and extensive years of experience form the tools with which we drive your success!

TECHNICAL CENTRE / BULK MATERIALS

In our reconceptualised technical centre, comprised of 100 m2state-of-the-art space, we put our designs to the test.

Here, we also examine specific performance requirements for our customers using their own bulk material. The bulk material lab is used for testing various bulk materials applied in order to ascertain their conveyability and screenability, for example, in practice. The performance data for bulk density, grain size distribution or moisture content can also offer numerous optimisation perspectives.

FINITE ELEMENT METHOD (FEM)

The Finite Element Method has proven to be exceptional in improving products and components.

AViTEQ relies on this state-of-the-art simulation process to consistently help detect hidden weaknesses and eliminate them. Thanks to FEM, we can confirm design reliability, as well as pass on cost savings due to these optimisations.

BULK MATERIAL DATABASE

Whether aerosil, cellulose, bauxite, quartz powder or xanthan gum, approximately 3,600 different bulk materials and their most important properties are stored in AViTEQ’s bulk material database.

This archive also hosts the results of experimental testing and a myriad of empirical values from experience. With almost 70 years’ experience in materials handling technology, our engineers have compiled a knowledge reservoir of inestimable value in a concise format.

QUALITY

AViTEQ’s facilities in Hattersheim and Oberboihingen are DIN ISO 9001 certified. Every internal operating process is subject to systematic monitoring by the respective accredited agency. We are also vigilant about the quality of our vendors, as well. Annually, our quality management department audits more than 80% of our suppliers according to DIN EN ISO 9001 standards. In order to satisfy escalating international safety requirements, we provide relevant safety certificates such as ATEX, CSA and Gost-R for selected systems and components. As a member of the European Hygienic Engineering & Design Group (EHEDG), we also satisfy the hygiene requirements within selected industries. AViTEQ is also a member of the VDMA and the DSIV.