Fluitec mixing + reaction solutions AG

About Us

Portrait

It was back in 1993 when Fluitec launched its first static mixers in the market back. Today, Fluitec is a reliable partner for high-quality products whose know-how spans a wide range of mixing, heat transfer, and reaction tasks in the chemical, petrochemical, pharmaceutical, environment, and food industries.

We work with steel, austenite, Duplex, Hastelloy, Inconel, titanium, and nickel. Static mixers made from PP, PE, PVC, PVDF, or PTFE can likewise be supplied.

Since investing in a modern laser welding line, we are also optimally equipped to serve you with apparatus with virtually any dimensions. Our vertical range of production is exceptionally broad.

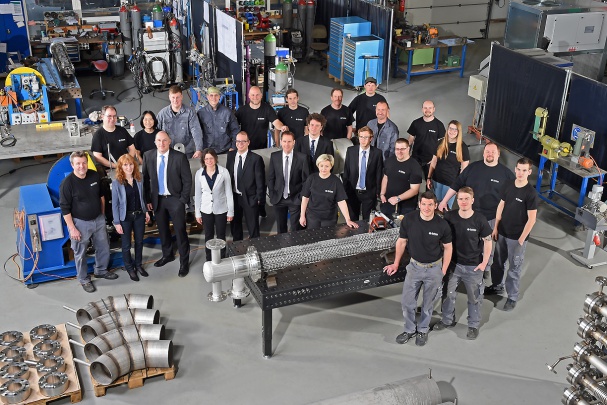

View of the production shop - apparatus weighing up to 3.5 tons is manufactured in-house

Laser welding line

The laser welding line allows us to create miniaturized, reproducible welds that would be impossible manually. Orbital or automated TIG welding systems are available for large sizes.

Approvals:

- AD 2000 HP0, Module A2 CE, ISO 9001

- ASME U-Stamp and China Stamp manufacture through a subcontractor

Our values

Research and development

In addition to continuously striving to perfect our mixing, heat transfer and reaction apparatus, we also conduct experiments in the Fluitec laboratory and carry out development work on behalf of our customers. We normally use reference fluids for this purpose to guarantee comparable results.

The Fluitec mixer / heat exchanger was invented in 2000, marking the company’s entry into the mixing and reaction technology segment. From there, it was only a small step to first complete and successfully commissioned in-line reaction system based on the Fluitec mixer / heat exchanger.

By 2002, the original building had become too cramped and so the firm relocated to Neftenbach. Parallel to numerous smaller projects, Fluitec’s engineers and technicians spent much of their time researching into scalable CSE-X reactors. Fluitec continued to grow steadily and within seven years was bursting at the seams; the move into new premises with a large workshop and experimental laboratory in 2009 was a logical decision.

The company had barely settled in when the new Fluitec Contiplant system revolutionised reaction technology.

Through ongoing research and development work, Fluitec is constantly striving to design new solutions tailored to users’ practical needs.

Fluitec 2018

These activities take place concurrently with the development of theoretical calculation methods and Fluitec’s leadership role when it comes to static mixer design is widely acknowledged. Over the last few years, Fluitec has intensified its efforts to optimise mixer structures, achieve new breakthroughs in mixer / heat exchanger technology and, in particular, build novel solutions for in-line reactions. Fluitec currently employs 28 staff.