- Products

- Catalogs

- News & Trends

- Exhibitions

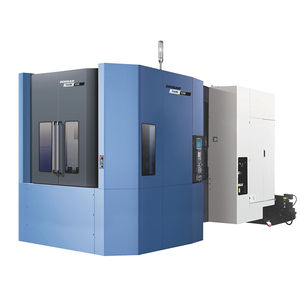

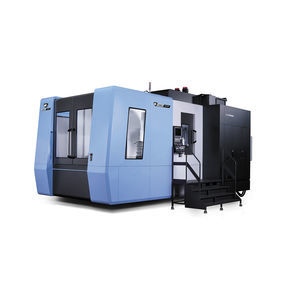

3-axis CNC machining center VM seriesverticalISO 50for molds

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- ISO 50

- Applications

- for molds, for matrices

- Other characteristics

- high-speed, high-performance, high-productivity, high-precision, contour

- X travel

Max.: 2,500 mm

(98 in)Min.: 1,050 mm

(41 in)- Y travel

Max.: 1,260 µm

Min.: 540 µm

- Z travel

530 mm, 560 mm, 625 mm, 800 mm, 900 mm

(21 in, 22 in, 25 in, 31 in, 35 in)- Rotational speed

6,000 rpm, 8,000 rpm, 12,000 rpm

(37,699 rad.min-1, 50,265 rad.min-1, 75,398 rad.min-1)- Power

15.6 kW, 18.5 kW, 22 kW, 26 kW, 30 kW

(21.21 hp, 25.15 hp, 29.91 hp, 35.35 hp, 40.79 hp)- Work feed X-axis

12,000 mm/min, 16,000 mm/min, 20,000 mm/min, 30,000 mm/min

(8 in/s, 10 in/s, 13 in/s, 20 in/s)- Work feed Y-axis

12,000 mm/min, 16,000 mm/min, 20,000 mm/min, 30,000 mm/min

(8 in/s, 10 in/s, 13 in/s, 20 in/s)- Work feed Z-axis

12,000 mm/min, 16,000 mm/min, 20,000 mm/min, 24,000 mm/min

(8 in/s, 10 in/s, 13 in/s, 16 in/s)- Table load capacity

Max.: 8,000 kg

(17,637 lb)Min.: 1,500 kg

(3,307 lb)- Weight

Max.: 31,000 kg

(68,343.3 lb)Min.: 9,000 kg

(19,841.6 lb)- Overall length

Max.: 5,645 mm

(222.2 in)Min.: 2,444 mm

(96.2 in)- Overall width

3,800 mm, 4,900 mm, 5,500 mm, 6,400 mm, 6,800 mm

(149.6 in, 192.9 in, 216.5 in, 252 in, 267.7 in)- Overall height

2,855 mm, 3,240 mm, 3,450 mm, 3,545 mm, 3,930 mm

(112.4 in, 127.6 in, 135.8 in, 139.6 in, 154.7 in)

Description

Low-vibration built-in spindle with the highest stroke in its class. Designed for both roughing and finishing, the VM Series comprises a number of machines with different sizes, capacities and capabilities.

TThe new machine design improves operator convenience and helps improve productivity an operational efficiencies.

Highlight

Reliability

Stability

Broad product line-up designed for customers’ different requirements

Complete line-up comprises

Highest reliability realized through excellent build quality and a wide range of spindle speeds

Dual contact spindle (standard)

Control solution for processing high-quality molds

Tool monitoring

Optimal feed control

VIDEO

Catalogs

No catalogs are available for this product.

See all of DN SOLUTIONS‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Turning center with turret

- 12 tools turning center

- Spindle lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.