- Building - Construction

- Construction and Mining Equipment

- Cone crusher

- Metso Corporation

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

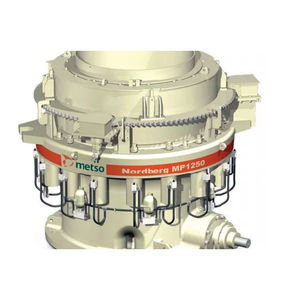

Cone crusher Nordberg® MP2500™stationaryprimarysecondary

Add to favorites

Compare this product

Characteristics

- Technology

- cone

- Mobility

- stationary

- Other characteristics

- primary, secondary, for building materials, for mineral material

- Capacity

Max.: 7,166 t/h

(4,388.4 lb/s)Min.: 2,153 t/h

(1,318.5 lb/s)

Description

Metso Outotec has four different families of cone crushers. All cone crusher families have their own applications and can apply to different operations. One of the families of cone crushers is named Nordberg® MP Series™ cone crushers. The MP used to only stand for maximum power, but now there is so much more to this cone crusher.

MP Series™ cone crushers are designed to have a high capacity and crushing force for size reduction. Nordberg® MP2500™ cone crusher brings the highest capacity cone crusher to bring benefits to any operation.

High availability

This cone crusher provides more availability for your crushing needs. A fully automated tramp release that passes uncrushables instantaneously allows the high crushing force to be maintained. After the uncrushable material passes through the tramp the production setting is automatically returned to where the cone crusher was set.

This crusher`s availability is further enhanced by the hydraulic clearing system. With a large vertical stroke, material can fall easily and this provides consistent stroke capabilities throughout the entire liners life.

High performance

MP2500™ brings cone crusher performance to a new level. MP no longer stands for Maximum Power, but now MP is Maximum Performance. Nordberg® MP2500™ still does provide the highest crushing power for any cone crusher in similar size.

Advanced crushing dynamics leads to more work per cycle. This cone crusher increases power draw so that will lead to an increase in capacity, and a higher power-to-production ratio giving energy efficiency too. So MP2500™ not only performs for you, but also performs to help with a cost-saving operation.

Catalogs

Related Searches

- Rail conveyor

- Belt conveyor

- Metso mill

- Metso crusher

- Roller rail conveyor

- Metso stationary crusher

- Horizontal grinding mill

- Mobile crushing and screening plant

- Impact crushing and screening plant

- Materials handling conveyor

- Jaw crushing and screening plant

- Bulk products conveyor

- High-capacity crushing plant

- Metso primary crusher

- Roller grinding mill

- Metso secondary crusher

- Building materials grinding mill

- Discharge conveyor

- Waste lump breaker

- Metso mineral material crusher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.