- Production Machines >

- Other Manufacturing Equipment >

- Roller mill

Roller mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 1,410 rpm

Output: 100 g/min

Machine length: 515 mm

Quadrumat Junior: New roller mill for user-friendly lab flour preparation What is it used for? The Brabender Quadrumat Junior is a universal laboratory roller mill with ...

Machine weight: 300 kg

... - ground meal - semolina bran - bran High efficiency and gentle grinding due to 4-roller system with hardened, profile-ground rollers 2 x 3 different grinding zones in one operation ...

Output: 200 g/min

Machine weight: 51 kg

... Throughput of 100g in approximately 3 minutes • - No wear on the grinding rollers • - Reproducible results Easy to use and constantly reproducible results The laboratory mill grinds and sifts ...

Motor power: 2, 3, 4, 6 kW

Machine weight: 250, 340 kg

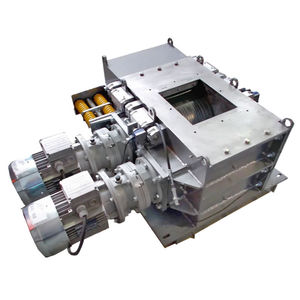

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers. The DLP Lump Breaker consists of a ...

Final grain size: 38 µm - 74 µm

Rotational speed: 1,480 rpm

Output: 4 t/h - 13 t/h

T130X Superfine Grinding Mill Optimized, Accurate, Reliable, Efficient T130X Superfine Grinding Mill evolves from TGM Super Pressure Trapezium Mill which has got many patents. Optimized ...

Henan LIMING Heavy Industry Science and Technology

Final grain size: 45 µm - 1,600 µm

Rotational speed: 990 rpm

Output: 7 t/h - 15 t/h

... Low consumption, Environmental friendly Quantity of roller (PCS): 4 Inner diameter of ring (mm): Ф1380 Main Mill Rotating speed (rpm): 990 Max. Feeding size(mm): 35 MTW European Trapezium Mill ...

Henan LIMING Heavy Industry Science and Technology

Final grain size: 45 µm - 1,600 µm

Rotational speed: 980 rpm

Output: 4 t/h - 10 t/h

Quantity of roller (PCS): 4 Inner diameter of ring (mm): Ф1100 Main Mill Rotating speed (rpm): 980 Max. Feeding size(mm): 30 MTW European Type Trapezium mill, that is our lastest ...

Henan LIMING Heavy Industry Science and Technology

Single Roller Mill EW-L Our Roller Mills have: A crushing ratio, usually 1:5 ... 1:15, whereby a maximum of 1:30 can be realized. An infinitely adjustable crushing ...

Double Roller Mill WS-L The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, ...

Output: 300 kg/h - 1,400 kg/h

Motor power: 7,500, 30,000 W

... production to fine grinding for the espresso and capsule sector. Design features: • One, two or three stage grinding • Two roller lengths are available • Central belt drive or individual drives • Easily accessible, ...

NEUHAUS NEOTEC

Output: 750 kg/h - 2,500 kg/h

Most advanced grinder for medium capacities and demanding specialty grinds. The newly designed coffee grinder NEOGRIND has been developed specifically for the high demands of filter coffee, pad/pod production (coffee capsules) and fine ...

NEUHAUS NEOTEC

Output: 0 kg/h - 500 kg/h

Motor power: 2,200 W

When it comes to applications with high demands on the particle size distribution, the laboratory grinder LWM 100 is the optimum machine. The fast roll change resulting from the special roll suspension and the precise control via a PLC ...

NEUHAUS NEOTEC

Output: 600 kg/h - 5,000 kg/h

Motor power: 237, 152 kW

Large output and high production efficiency Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets ...

Rotational speed: 5,050, 1,850, 2,580 rpm

Motor power: 3 kW - 37 kW

... modification production line of a mineral products company in Fujian 1t/h Calcium carbonate modified production line of a paper mill in Shandong 1t/h

Output: 6 t/h - 350 t/h

Motor power: 75 kW - 3,300 kW

Machine length: 2,400 mm - 7,200 mm

WTM intelligent vertical mill is dedicated to the high-efficiency dissociation of minerals, providing users with energy-saving, consumption-reducing, quality-enhancing and efficiency-enhancing solutions, realizing maximum ...

Output: 30 t/h - 7,400 t/h

Motor power: 45 kW - 7,000 kW

In recent years, with the continuous consumption of high-grade ores, the characteristics of poor, fine and miscellaneous minerals have become prominent, and the sorting and processing of low-grade and refractory ores has become the main ...

... Furthermore, the flaking roller mill is equipped with robust flaking rollers which are made of a special cast steel. Hot-pressed shaft ends and easy access to all wear parts provide quick ...

Crushing Mill OLCB The high-capacity Bühler crushing mill OLCB is a true all-rounder talent: It can be applied for cracking oilseeds such as soybeans, sunflower seeds, rapeseeds, and corn (maize) as ...

Bühler Group

Flaking Mill DOQB As a manufacturer of food processing machinery, Bühler is also a leading supplier of oilseed processing equipment used in oilseed preparation and handling. The Bühler flaking mill ...

Bühler Group

Flaking Mill DOZC As a manufacturer of food processing machinery, Bühler is also a leading supplier of oilseed processing equipment used in oilseed preparation and handling. Bühler's proven flaking mill ...

Bühler Group

Rotational speed: 360, 428, 270, 348 rpm

Motor power: 1 kW

Machine length: 610, 660, 762, 927, 1,676 mm

... non-stainless steel external surfaces coated with a white two-part epoxy paint • Safety trip switch across the top of the mill AVAILABLE OPTIONS: • Stainless steel type 440C hardened rolls and Tefl on end plates ...

Final grain size: 100 µm - 100 µm

Output: 60,000 kg/h - 480,000 kg/h

Motor power: 2,200, 4,000, 3,000 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 100 µm

Output: 1,100,000 kg/h - 6,700,000 kg/h

Motor power: 11,000, 7,500, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 1,000 µm

Output: 400,000 kg/h - 1,000,000 kg/h

Motor power: 4,000, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Output: 150 kg/h - 200,000 kg/h

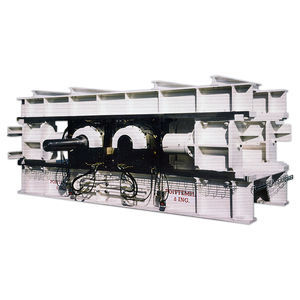

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum ...

Output: 5 t/h - 500 t/h

DESCRIPTION The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill ...

Output: 1 t/h - 200 t/h

... Dynamic classifier. This type of separator is usually installed on Pendulum Roller mills but can be used in a pneumatic circuit, alone or combined with a Pulverizer or Ball mill ...

Output: 60 kg/h - 110 kg/h

grinder CRICK-CROCK for toasted nuts (hazelnuts, peanuts, walnuts, almonds, etc.), nougat, crunchy, cookies and chocolate. The machine is composed of modules of rotary blades for the production of different grain size or powder and ...

Motor power: 1.5 kW - 45 kW

Machine weight: 1,200 kg - 11,000 kg

... products : Fertilisers, Resins, Salts, etc. Options : Roller cooling Side panel heating Cleaning combs Cleaning scrapers Grinding machine for smooth rollers Rotation controller

... products. Design: - Roller removal both to the front and to the side possible - Smooth operation, low wear and easy maintenance due to direct drive without chains, belts or gear wheels - One roller ...

Using the KAHL crushing roller mill, legumes, oilseeds, and feed mixtures can be crushed efficiently and with a considerably lower expenditure of energy compared to the hammer mill. The ...

Motor power: 200 W

Machine length: 40 cm

Machine width: 26 cm

The MPC mill is ideal for fine trituration and homogenization of ointments, creams, pastes, gels and suspensions: it reduces particles to the optimal size for absorption into the body. The mill features ...

Rotational speed: 220, 330 rpm

Output: 200 kg/h - 600 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

Rotational speed: 220, 330 rpm

Output: 800 kg/h - 1,200 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

During metal scrap processing, conveyance systems using augers or steel belts frequently fail to consistently move bushy bundles of metal scrap because the augers and steel belts are unable to grab hold of the stringy wads. This limitation ...

Output: 175 t/h - 1,000 t/h

Motor power: 1,050 ch - 1,200 ch

... Series is essential for any large-scale wood waste and land-clearing grinding operation. Equipped with an internal drive feed roller which allows easy maintenance access and has less moving parts, all while ensuring minimal ...

Output: 1,000 kg/h

The PASTA GRIDER ROLLING MILL is a machine specifically conceived for pasta factories. It is used to transform the rejected pre-shredded pasta into semolina, in order to be mixed to the main semolina mass and sent to ...

... auxiliary machine used for the disintegration of the plates of products produced by the pressure of the cylinders of the rolling mills. Its disruptive action is designed to crumble the plaques by pulverizing the flour ...

... machine used for the disintegration of the plates of floury products produced by the pressure of the cylinders of the rolling mills. Its action is similar to that of the disruptor but much more intense. Therefore, ...

Final grain size: 40 µm - 300 µm

Output: 1,500 kg/h - 22,000 kg/h

Motor power: 45, 90 kW

... competitive cost with the introduction of hot gas through the mill. The ROLLER MILL can operate in closed circulation of inert gas, controlled by suitable safety equipment. In these ...

Output: 3 t/h - 83 t/h

... , barite, marble, talc, coal powder, etc. Lower Maintenance Costs - Grinding Roller Adopts Dilute Oil Lubrication Grinding roller of MB5X Pendulum Roller Grinding Mill ...

Shibang Industry & Technology Group Co., Ltd.

Output: 4 t/h - 300 t/h

... of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, ...

Shibang Industry & Technology Group Co., Ltd.

Output: 4 t/h - 300 t/h

... of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, ...

Shibang Industry & Technology Group Co., Ltd.

Output: 30 t/h - 60 t/h

Motor power: 37, 55, 75 kW

The ladder type dry mixed mortar production line is compared with the tower type, the equipment height is relatively low, the equipment occupies a large area, the base load is small, and the energy consumption is relatively large. The ...

Motor power: 37, 55, 75, 110 kW

The tower type dry mortar production line, in accordance with the procedure from top to bottom arranged to produce, low energy consumption, small footprint, batching process almost no cross mixing; base load, module development is finished, ...

Output: 40, 60, 80 t/h

Motor power: 30, 37, 55 kW

The overall structure of the station type dry mixed mortar production line is the layout of the raw material tank around the mixing main building. The structure is similar to the commercial mixing plant, and the overall structure is relatively ...

Output: 1,000 kg/h

... manufactured by Alexanderwerk. This grating and shredding machine is designed for inline installation, but can also work as s mobile unit. It has a cylinder diameter of 165 mm, and can produce throughput rates up to 1,000 ...

Output: 10,000 kg/h

... Shredders are primarily utilized for applications that involve inline installation functions. They are also used as alternative mobile units, complete with grating/shredding cylinders with diametric measurements of 340 ...

Output: 1 kg/h - 45 kg/h

Motor power: 75, 185, 315 kW

Dolomite powder making machine also be called dolomite grinding mill, can be used in more than 300 kinds of minerals powder 300-2500 mesh grinding, besides dolomite, it can be used in calcium carbonate, kaolin, clay, ...

Shanghai Clirik Machinery

Rotational speed: 120 rpm - 240 rpm

Output: 400 kg/h - 30,000 kg/h

Machine length: 13,900, 14,700 mm

... the grinding mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers ...

Shanghai Clirik Machinery

Output: 3 t/h - 19 t/h

Motor power: 250, 315, 355 kW

... back for regrinding. Advantages of Ultrafine Vertical Mill(Upgrade product of HGM Micro powder mill): 1.High grinding efficiency: save 20~30% power consumption compared with the ball mill. ...

Shanghai Clirik Machinery

Your suggestions for improvement:

A roller mill uses a pair of parallel cylindrical rollers to pulverize material to a desired particle size.

ApplicationsRoller mills have replaced rotary millstones in the food industry. They are also common in pharmaceutical and mining applications.

TechnologiesRoller mills comprise one or more pairs of parallel cylindrical rollers. These can turn at the same or at different speeds.

How to chooseChoice of roller mill will depend on desired output. This is determined by cylinder diameter and speed, as well as the position and dimensions of the grooves cut into each one. The ground product passes through a sieve to ensure proper particle size.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining