- Products

- Catalogs

- News & Trends

- Exhibitions

Laser line triangulation scanner Q6 series2/3-axisfor production linesfor measuring

Add to favorites

Compare this product

Characteristics

- Number of axes

- 2/3-axis

- Applications

- for production lines, for measuring, shape measurement, for surface inspection, for welding inspection, for robotic dimensional inspection, profile, for detection, for large products, for quality control, for robots, for OEM, for packaging machines

- Technology

- laser line triangulation, optical

- Configuration

- compact, fixed, in-line

- Other characteristics

- high-speed, high-resolution, rugged, with blue laser diode, non-contact, robotic

- Measuring distance

Max.: 800 mm

(31 in)Min.: 15 mm

(1 in)

Description

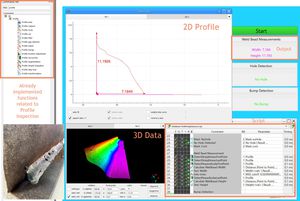

QuellTech laser-scanners make use of the triangulation principle to detect the two-dimensional profile of surfaces. By means of optical components, a point-shaped laser beam is expanded to a line and projected to the object of interest. The diffuse light of the reflected laser line is captured by an objective at a certain angle and then directed to a two-dimensional receiver chip.

Based on distances and angles known, a precise calibrated height value (z) is calculated for each pixel in the x level (laser line), resulting in a precise profile in the x-z plane of the sample. If the scanner is guided over the sample (y axis), a series of profiles is created forming a three-dimensional point cloud in space. This point cloud can be subjected by dimensional control carried out by the software.

Q6 laser scanner, a heavy-duty series for most demanding measuring tasks

QuellTech Q6 laser scanner are ideally suited for industrial applications, requiring maximum precision and process stability at high traverse speed:

High resolution and profile speed of 20.000 profiles/s and up to 82 Mio points/s

• X-Measuring range from 45 to 1000 mm

• Z-Measuring range (height) from 15 to 800 mm

• Laser wavelength blue 405nm or 450 nm, red 650 nm

The Q6 series is also suitable for connecting several scanners in parallel in master/slave mode. Different optical powers are available from 1 mW to 160 mW. These different power classes and wavelengths can be optimally adapted to the surface of a measurement object.

Q6 laser scanner – Further Properties

• Resolution down to 0,24 µm (numeric resolution)

• Special algorithms for very glossy material

VIDEO

Catalogs

No catalogs are available for this product.

See all of QuellTech GmbH‘s catalogsRelated Searches

- Laser scanning system

- Measurement scanning system

- Inspection scanning system

- High-resolution scanning system

- High-speed scanning system

- High-precision scanning system

- Compact scanning system

- Optical scanning system

- Profile scanning system

- Rugged scanner

- Automated scanning system

- Detection scanner

- Measuring scanning system

- Ethernet scanner

- Quality control scanning system

- Fixed scanning system

- Non-contact scanner

- Surface inspection scanner

- Large part scanner

- Welding inspection scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.