- Metrology - Laboratory

- Analytical Instrumentation

- Ultrasonic probe

- SYNERGYS TECHNOLOGIES

- Products

- Catalogs

- News & Trends

- Exhibitions

Ultrasonic probe LKS1000for gas leak detectorsfor bearing condition monitoringcontact

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic

- Applications

- for gas leak detectors, for bearing condition monitoring

- Other characteristics

- contact

Description

The 3rd of LEAKSHOOTER® was developed for big industrial plants with a big steam generating system, and many steam traps.

Steam traps control was usually done by ear with a contact probe used as a stethoscope.

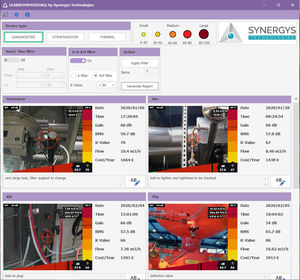

LKS1000-V.3+ is the 1st ultrasonic detector to have a dedicated steam traps control programm STRAPSHOOTER®+.

Moreover, we added an infrared camera 80*60px to measure temperature on piping.

After 1 year of use, main improvement requests :

Compatibility of the programm to a larger range of steam traps, thermodynamic, thermostatic and ball float steam traps.

Infrared camera resolution.

The new version LKS1000-V.3+ PRO

A completely reworked programm, which allowed a much more accurate steam traps auto-diagnostic on a large range of traps.

Besides we realised that the embedded infrared camera was often used for all kind of applications in predictive maintenance.

That is why we decided to integrate in the PRO version an upgraded camera with a 160x120px resolution.

The STRAPSHOOTER® + software is now compatible with thermostatic, thermodynamic and ball float steam traps.

With the new LEAKSHOOTER® V.3+pro you will be able to monitor quickly and easily all kind of steam traps on the plant. Il permet très

Catalogs

Other SYNERGYS TECHNOLOGIES products

Ultrasonic compressed air leak gas steam and vacuum detection

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.