- Products

- Catalogs

- News & Trends

- Exhibitions

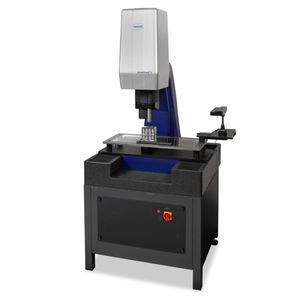

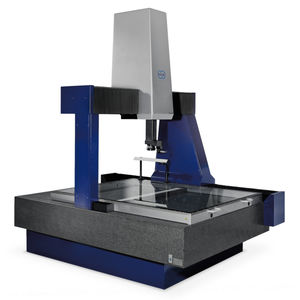

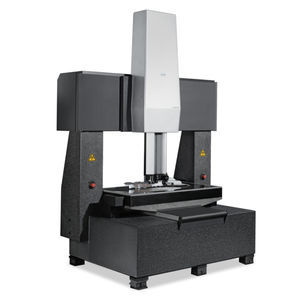

Computer-controlled coordinate measuring machine QuickInspect goosenecktabletophigh-precision

Add to favorites

Compare this product

Characteristics

- Control

- computer-controlled

- Structure

- gooseneck

- Other characteristics

- high-precision, automated, tabletop

- X travel

Min.: 800 µm

400 µm, 250,000 µm

(10 in, 16 in)Max.: 225,000 µm

(9 in)- Y travel

Min.: 600 µm

200 µm, 125,000 µm

(5 in, 8 in)Max.: 190,000 µm

(7 in)

Description

Measurement in the sensor's field of view or with measuring range according to requirements for shopfloor and measuring room

The QuickInspect enables the complete capture of the workpiece in one image and ensures easy operation and short measuring times. Focusing is not necessary with most device variants due to the large depth of field range of the telecentric lenses. The workpiece is placed on the measuring table of the digital measuring projector, automatically detected and measured. With the QuickInspect MT, even small or highly accurate features on larger objects can be displayed and optically measured in the raster image with almost any resolution (patent). The area of application is 2D workpieces.

• 10x optoelectronic zoom and electronic zoom with almost any magnification

• 8-segment darkfield incident light and Werth FlatLight possible

• For high magnifications, a convenient focus function in the measurement software supports easy focusing

• Functional inspection and colour-coded deviation plot with Werth BestFit or ToleranceFit®

• Comparability with conventional coordinate metrology through specification according to DIN 10360 or VDI 2617

Accuracy

Permissible length measurement error up to 0.25 µm

VIDEO

Catalogs

The Multisensor

20 Pages

Related Searches

- Measuring machine

- Touch probe head

- Optical measuring machine

- Laser scanning system

- Measurement scanning system

- Automatic measuring machine

- High-precision measuring machine

- Measurement touch probe head

- CMM

- Parts measuring machine

- Distance measuring machine

- Inspection scanning system

- Laser measurement system

- High-speed scanning system

- Multi-sensor coordinate measuring machine

- Video measuring machine

- 3D measuring machine

- Bridge coordinate measuring machine

- Length measuring machine

- XY scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.