- Machine-tools >

- Machine Tool Accessory >

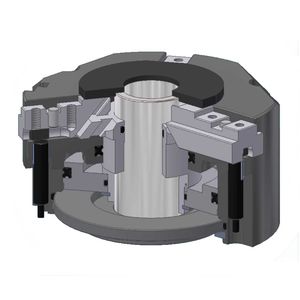

- 3-jaw turning chuck

3-jaw turning chucks

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 59.3 rpm - 291.5 rpm

Outer diameter: 160 mm - 1,000 mm

... highest gripping force. Jaws can be changed in less than a minute, and jaw sets can be radially adjusted and reversed. The HG-N Chucks utilize SMW's original jaw design, ...

SMW AUTOBLOK

Rotational speed: 3,150 rpm - 8,000 rpm

Gripping force: 48 kN - 250 kN

Outer diameter: 110 mm - 400 mm

The Duro-A is a three-jaw chuck with a through-hole that can be clamped automatically (hydraulically) by a CNC machine. It is mainly used forturningcylindrical and disc-shaped blanks. Stable damping using ...

RÖHM GmbH

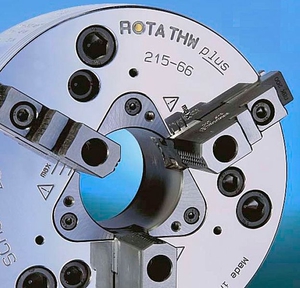

Rotational speed: 3,500, 4,000, 4,700, 6,000, 6,300 rpm

Gripping force: 100, 240, 180, 135, 64 kN

Outer diameter: 180, 215, 260, 315, 400 mm

... clamping Base jaws with straight teeth A RC Application area Premium power chuck with through-hole for the machining of bar, pipes and discs. Maximum speeds and flexible use thanks to quick jaw ...

RÖHM GmbH

Gripping force: 0 kN - 115 kN

Outer diameter: 74 mm - 1,250 mm

... Duro-M is a manually geared scroll chuck with through-hole, drilling and turning jaws with cylindrical mount. It is mainly used on conventional turning machines for machining ...

RÖHM GmbH

Gripping force: 1,000 N - 10,100 N

Stationary 3-jaw-clamping-chuck, pneumatic Through central hole up to 60.5 mm Self-centering Clamping force up to 10.100N Stroke up to 32mm Stroke control Rating IP 40

Gripping force: 940 N - 16,650 N

Stationary 3-jaw-clamping-chuck, hydraulic-pneumatic Self-centering Compact from diam. 64 mm Clamping force up to 16.650N stroke up to 50 mm Stroke control Rating IP 40

Outer diameter: 160 mm

MCL stroke 160mm for jaw 3-finger self centering

Rotational speed: 3,600 rpm - 6,000 rpm

Gripping force: 41 kN - 160 kN

Outer diameter: 165 mm - 315 mm

Fast jaw change with quick change design and high repeatability – that is what makes the B-Top jaw chuck product line so flexible. Particularly for small lot sizes. Thus in most cases ...

Rotational speed: 0 rpm - 5,400 rpm

Gripping force: 74 kN

Outer diameter: 215 mm

... thanks the modular system I.D., O.D. or jaw clamping – it‘s easy with the B-Top3 modular system. Everything fits together. With MANDO Adapt segmented mandrel, you can change to perfect I.D. clamping ...

Rotational speed: 4,000, 3,600, 6,000, 5,400 rpm

Gripping force: 74, 41, 160, 115 kN

Outer diameter: 215, 165, 315, 260 mm

... small lot sizes Fast jaw change with quick change design and high repeatability – that is what makes the B-Top jaw chuck product line so flexible. Particularly for small lot sizes. ...

Rotational speed: 1 rpm - 6,000 rpm

Gripping force: 1 kN - 80 kN

Outer diameter: 165 mm - 370 mm

... dealing with hard turning. Radial runout ≤ 0.005 mm Accuracy of jaw change over ≤ 0.002 mm No need for regrinding clamping faces after jaw change-over Completely sealed off and ...

Rotational speed: 1,400 rpm - 3,200 rpm

Gripping force: 3,100 daN - 6,900 daN

Outer diameter: 160 mm - 430 mm

... -DUX chuck is balanced following the ISO3089/74 rules and supplied with the warranty and testing certificates. The chucks with diameter 365 and 430mm, suitable for heavy-duty machinings, keep the same ...

Gripping force: 16 kN - 98 kN

Outer diameter: 165 mm - 315 mm

... pneumatic chuck fixtures for indexing tables - Ø 165 - 315 mm - 2 and 3 jaws Application/customers benefit Self centering rotating chuck fixtures ...

OML

Hardinge HQC Quick-Change collets can be changed from one size collet to another size in less than 20 seconds. More Uptime on Multi-Spindle Automatics The HQC System requires less draw bar force to adequately grip the bar, greatly ...

Hardinge Workholding

Rotational speed: 6,000, 4,500, 5,000, 7,000, 3,500 rpm

Gripping force: 143, 56, 36, 110, 85 kN

Outer diameter: 305, 210, 135, 169, 254 mm

... while maintaining accuracy and repeatability PACKAGE INCLUDED - Chuck and Mounting Bolts - Soft Jaws (1 Set) - Hard Jaws (1 Set) - T-Nuts (1 Set - T-Nuts Bolts - Key for Chuck ...

Ozkayali Workholding and Spanntechnik

Rotational speed: 4,500, 5,000, 3,500, 6,000, 7,000 rpm

Gripping force: 143, 56, 36, 110, 85 kN

Outer diameter: 135, 210, 169, 305, 254 mm

... maintaining accuracy and repeatability PACKAGE INCLUDED - Chuck and Mounting Bolts - Soft Jaws (1 Set) - Hard Jaws (1 Set) - T-Nuts (1 Set - T-Nuts Bolts - Key ...

Ozkayali Workholding and Spanntechnik

Rotational speed: 7,000, 4,500, 6,000, 5,000, 3,500 rpm

Gripping force: 85, 143, 56, 36, 110 kN

Outer diameter: 135, 210, 254, 169, 305 mm

... while maintaining accuracy and repeatability PACKAGE INCLUDED - Chuck and Mounting Bolts - Soft Jaws (1 Set) - T-Nuts (1 Set - T-Nuts Bolts - Key for Chuck İnstallations - ...

Ozkayali Workholding and Spanntechnik

Through-hole 3-jaw power operated chuck. (High speed and high accuracy) This model provides high-repeatability with cross-key structure that does jaw positioning. ...

... 6”-21” chuck sizes HHA Series Closed Center 3-Jaw Power Chuck A family of thirteen units from 21″ to 40″ in diameter, each providing rigid direct mountings,lubrication ...

Rotational speed: 6,000, 4,000, 3,500, 3,000 rpm

Gripping force: 4.1, 6.8, 17, 29.2, 46 kN

Outer diameter: 250, 80, 200, 100, 150 mm

... minimal distortion. All models, except the 3-50, feature a coolant or air passage through the center of the chuck. Chuck Accuracy .00005" (0.0012mm) TIR is standard .00002" (0.0005mm) ...

Microcentric

Rotational speed: 2,000, 3,000, 2,500, 4,000 rpm

Gripping force: 6.8, 12.1, 25.4 kN

Outer diameter: 150, 200, 250, 100 mm

Long stroke air chucks feature extended jaw opening for load clearance or to clamp a range of diameters without changing top jaws. Long stroke chucks are available in ...

Microcentric

Gripping force: 11.3, 14, 25.8 kN

Outer diameter: 150, 80, 100 mm

HST High Speed Air Chucks feature a titanium chuck body and are actuated by a patented external wedge design that maintains clamping force at high spindle speeds without counterweights. This revolutionary ...

Microcentric

Rotational speed: 0 rpm - 5,000 rpm

Gripping force: 0 kN - 86 kN

Outer diameter: 30 mm - 210 mm

... power chuck can be used with both hard and soft jaws. Chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver ...

Kitagawa Europe

Outer diameter: 102 mm - 830 mm

Automatic self-centering BIG THRU-BORE CHUCK with built-in pneumatic cylinder

ROTOMORS

... another without remachining of the top jaws, without setting time in less than one minute Interchangeable jaws: hard jaws, smooth, corrugated, jaws with clamping fingers, ...

TOBLER

Gripping force: 5,000 N

... Recommended tightening torque, manual chucks: 4 Nm. - Permitted torque for 25 mm holder: 10 Nm - Permitted torque for 30 mm holder: 25 Nm - Maximum flushing pressure: 15 bar* - Clamping force: 5 000 N *Manual chucks ...

... hardened and ground forged scroll • Each scroll precisely balanced • Fully hardened and ground jaw teeth and guides • Each chuck is balanced • Chuck adapter plates require no machining

The 2/3QLC wedge hook chuck is the universal clamping device for the contract lathe operator changing between 2- and 3-jaw chucks. It ...

ITW Workholding

Rotational speed: 200 rpm

... time-delay, wait for input signal, and other motion control features. This new MRC3-57 series replaces our previous MRC3-42 rotary chucks. Same 3" chuck ...

Excitron Corporation

Properties and application: Cast iron lathe chuck Mounted on adapter plate The set includes: 1 set of external solid jaws, 1 set of internal solid jaws, ...

Zakład Obróbki Skrawaniem Darmet sp. z o.o.

Rotational speed: 300 rpm - 3,500 rpm

Three-jaw lathe chuck ZENTRA - centre mount (DIN 6350) - one-piece / two-piece jaws - cast iron or steel

MACK Werkzeuge AG

Outer diameter: 55 mm - 160 mm

The DBF series is manufactured by Koch Maschinenbau GmbH & Co. KG. It is a hand tightening chuck, with a diameter range from 55 mm to 160 mm. The DBF is made from stainless steel, and has a flat and light design. Features ...

Rotational speed: 3,150 rpm - 8,000 rpm

Gripping force: 20 kN - 100 kN

BERG power operated chucks type KH are designed for high speed, high capacity lathes. They stand out for their high clamping force and precision, a particularly large open centre for bar stock, as well as high maximum ...

Berg & Co. GmbH Spanntechnik

... reliability, repeatability, concentricity and productivity. Chuck sizes: 3" (76mm) to 12" {305mm). "Coolant-thru" models. Precision top jaws shipped same day. Custom-designed jaw ...

Manual self-centring chuck: It is possible to mount manual self-centring chuck.

Compressed air operated self-centring chuck: It is possible to mount compressed air operated self-centring chuck, which, thanks to the machine software, are managed by the NC system.

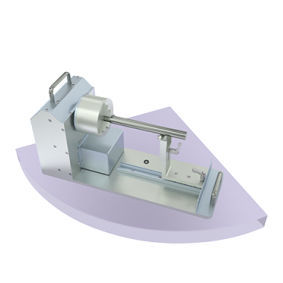

... rotation (partial apparatus) is used for the segmentation of the mantle surface on cylindrical components. A manual 3-jaw chuck is included in the scope of delivery. In order to ...

Your suggestions for improvement:

The three-jaw chuck is the most common type of lathe chuck for holding rotating workpieces. This self-centering chuck can be either manual or power actuated. It also can be used on rotary indexing tables.

ApplicationsThese chucks can hold small, medium and large workpieces for all types of turning applications, as well as for grinding. They also can be mounted on rotary tables for dimensional measurements.

TechnologiesThe three-jaw chuck is almost always a self-centering chuck, holding the workpiece in radial symmetry. There are both through-hole and closed-center models.

How to chooseBe sure to determine the size range of the workpieces the chuck will hold. Its clamping force is another important consideration.

- Self-centering

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining