- Hydraulics - Pneumatics >

- Filter and Separator >

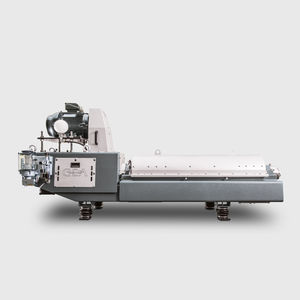

- Dehydration decanter

Dehydration decanters

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption. Flottweg ...

Flottweg SE

... costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially ...

Flottweg SE

... shows throughout the manufacturing process. The newly developed Flottweg Z3E brings us a huge step towards that goal. This decanter centrifuge is flexible, maintenance-friendly, and powerful. With its easy-to-open ...

Flottweg SE

... Petrolchemical Food Zootechnical USES Sludge Dehydration Extraction, refining and recovery of fuel oils Sewage treatment Sludge treatment from food processes SERVICES Mobile plant renting for sludge dewatering Technical ...

Plant and equipment for the dewatering of sludge from wastewater and industrial process centrifugal extractor. New Decanter with openable cover structure. FIELDS OF USE Ecology / Depuration Industrial Chemical / Petrolchemical Food ...

Plant and equipment for the dewatering of sludge from wastewater and industrial process centrifugal extractor. FIELDS OF USE Ecology / Depuration Industrial Chemical / Petrolchemical Food Industry Zoo-technical APPLICATIONS Dewatering ...

... and objectives. ANDRITZ decanter centrifuge range for environment ANDRITZ decanter centrifuge D, a reliable solution with high versatility for a wide range of applications. ANDRITZ decanter ...

... transported by the scroll to the solids discharge. On decanter type chemMaster series, the clarified liquid is discharged under pressure by use of a centripetal pump. CIP-compatability of the decanter ...

GEA Westfalia Separator

The Sweco® CD500 & CD600 Decanting Centrifuges boast infinite speed adjustability of main bowl drive and backdrive (differential). Utilizing variable frequency drives on all motors allows low amperage start-ups and eliminates troublesome ...

SWECO

... discharged matter. Added to this, the long service life and low standstill times of Hiller decanters also ensure a high level of cost efficiency. Benefits of the Hiller decanter technology: Maximum ...

Hiller GmbH

... importance of using a Decanter Screenbowl Centrifuge that maximises recovery rates. We also know that the separation process requires robust equipment that has a long wear life, and an easy parts exchange process. Our ...

FLSmidth Dorr-Oliver Eimco

... separate into liquid and solid components. The most commonly used technologies for sludge dewatering are pressing and centrifuging. EQUIPMENT NEEDED FOR SLUDGE DEWATERING The choice of sludge processing ...

GN Decanter Centrifuge is designed for the drilling mud solids control and oilfield waste management.GN VFD drive decanter centrifuge with variable speed allows drilling contracor or mud service company ...

... maximizing barite recovery or looking to get the most out of your “zero-discharge” closed-loop system, Elgin’s field proven decanter centrifuges are a perfect choice. With over 500 units installed worldwide, Elgin introduces ...

Elgin Separation Solutions

The dewatering system is widely used in oxidation ditch, AB, A/O, A/0, SBR, MBR, anaerobic fermentation and other processes, as well as traditional wastewater treatment processes such as urban domestic sewage, municipal sewage, garbage ...

ZK SEPARATION

DDE Series Decanter Centrifuge is a decanter centrifuge: horizontal rotating bowl, 2-phase configuration, continuous discharge of sludge through scrolling conveyor, dual-drive type, variable differential ...

Our decanter is a circular tank where particles in suspension or sludge are separated from the water. They are then concentrated and discharged from the bottom while the clarified water overflows from the top of the unit ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining