- Environment - Health - Safety >

- Water Treatment >

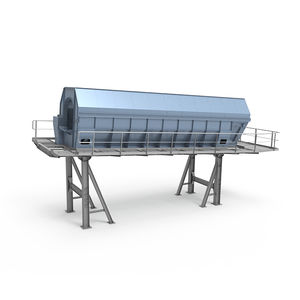

- Drum screen

Drum screens

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... multiple pieces of equipment. SPIRAMATIC VSA Fine Drum Screens consist of a rotating drum screen, a conveyor screw, and a compaction zone. Depending on the application, ...

... consist of a stainless steel screen drum contained in a stainless steel tank. The drum consists of a wedge wire screen. Due to the trapezoidal screen ...

... Rotating Drum Screens are suitable for pre-treatment of both municipal and industrial waste water treatment, as well as MBR plants. RTV Drum Screens are made up of a ...

... mesh. The screened flow powers a paddle wheel which is mounted below the mesh drum. This drives the brush wheel via a belt and pulleys and the brushes clean the mesh drum, returning any solids back ...

External Rotary drum screen is a rotating stainless-steel wedge wire cylinder which is fed externally. As the solids are captured on the face of the screen, they are removed by a discharge ...

... wastewater enter the rotary drum screen from the inside rotating drum. The larger than screen mesh solids are captured on the filter screen and Water ...

Our drum screen has built a strong reputation for itself thanks to its robust design, effective screening operation and outstanding service life. Trusteel Recycling is your trusted partner for waste ...

The ROTAMAT Rotary Drum Fine Screen Ro 2 or Perforated Plate Screen RPPS, engineered by Huber Technology, is composed of a stainless steel material and is acid-treated in a pickling bath. ...

Huber Technology

... CIL/CIP plant Our engineers have worked hard to make our Carbon Retention Screens the most effective and longest-lasting interstage screening solution on the market. Our screens are customised to suit ...

Processors can gain significant savings with the Double Drum Screen two-in-one screening system to reduce industrial waste and increase product recovery. The Double Drum screen ...

Lyco Manufacturing, Inc.

The rotary WPL Inlet Industrial Drum Screen is designed for separation of screenings from industrial and municipal wastewater effluent, and particularly for water containing viscose and fibrous elements. ...

... agglomerate and absorb grease as they tumble towards the discharge end of the drum screen, cleaning the openings, allowing liquid to drain, and enhancing the effectiveness of the rotary screen’s ...

Headworks Bio Inc.

... cylindrical screen where the doctor blade removes them efficiently. The screened effluent passes again through the cylinder and carries on an efficacious backwashing of the screen openings. Thanks to ...

The motorized BASKET SCREEN is made of a rectangular basket lifted out of the well and lowered by an electrical winch. The guidance of the basket is made by two guide rails fixed at the structure in which the basket is ...

Equipwater

... pieces of equipment. Description SPIRAMATIC VSA Fine Drum Screens consist of a rotating drum screen, a conveyor screw, and a compaction zone. Depending on the application, ...

The sewage is pumped into the main tank, complete with diffuser compartmen, to allow better distribution over the arched filtration panel. The water flows through holes and comes out on the far side of the filter freed from the residual ...

COSME S.R.L

... area can be between 1 / 0,5 mm and 10 / 6 mm. Cleaning of the drum is effected by a spray nozzle bar and a brush. Drum and conveyor are driven by a geared motor. The FSM rotary drum ...

... surface of the screen drum. The solids in the liquid are retained on the outside drum screen surface and removed by the doctor blade into a suitable container or a conveying ...

Sparta’s robust drum rotating screen is the perfect screen for the toughest applications. This low maintenance, non-wrapping, self-cleaning screen Is often used to screen ...

... mesh. The screened flow powers a paddle wheel which is mounted below the mesh drum. This drives the brush wheel via a belt and pulleys and the brushes clean the mesh drum, returning any solids back ...

... equipment invest and robust construction and long service life. Drum screen drives material in a rotary motion to separate materials, with its drum installed in slightly inclined position, ...

... influent hits the turning screen, the solids are caught inside the cylinder and the liquid passes through the screen into the process or on for further treatment. Diverters on the cylinder move the solids ...

Parkson Corporation

... for its overall length, the Cribus set the standard in the compact class. Its large-diameter drum improves screening performance, and generous spacing between drum and side walls ensures trouble-free ...

HANTSCH SAS

... work with the highest efficiency thanks to the holes of different diameters in its drum and its inclined design. Rotary screens work on the principle of rotating a drum with holes ...

Rotating barrel (drum) is capable to do uniform sifting of the most complicated materials, using the feed motion mechanism with automated load control in the best way. Rotating screen has a large sifting ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining