- Industrial machines and equipment >

- Surface Treatment >

- Large series galvanizing

Large series galvanizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Turning Parts, Metal Parts Manufacturer, Custom CNC machining parts. According to customer requirements, galvanized surface treatment of product raw materials •Material: Steel, Brass, Aluminum, Stainless Steel •Surface Treatment/Finishing: ...

Complementary processing techniques Thanks to the experience developed throughout the years, Fotomeccanica is able to provide additional processing techniques to complete the photo-etching process, such as high-quality galvanic plating ...

FOTOMECCANICA SRL

Hot-Dip Galvanizing or HDG is a process in which zinc bonds to steel at the molecular level to produce a four-layer corrosion-resistant finish. The first three layers are zinc-iron alloy layers that are actually harder ...

SUTOR TECHNOLOGY CO., LTD

... demands of quality and service lives are crucial. Hot-dip galvanizing is a process where the item for galvanizing is cleaned of grease, oil, mill scale, rust and other impurities. Hot-dip galvanizing ...

With hot-dip galvanizing, the material to be galvanized is immersed in molten zinc. As a consequence of the mutual diffusion, a layer of differently composed zinc-iron alloy layers forms between the zinc and the steel ...

The ISO 1461 hot dip galvanizing process consists of immersing steel parts in a molten zinc bath (approximately 450 ° C) to produce a protective anti-corrosion coating on the steel. ISO 1461 hot dip galvanizing ...

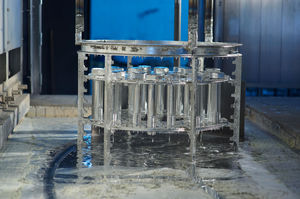

Electrogalvanizing of rack objects For all kinds of machine components and technical items electrogalvanizing with varied chromating is still the most frequently-employed protection against corrosion. This process is particularly indispensable ...

... experience we offer: Hot Dip Galvanizing, effective protection from corrosion and environmentally friendly. Advantages of Galvanizing Economic Benefits – With a preliminary expense of less than ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining