- Packing - Handling - Logistics >

- Conveying >

- Roller feeder

Roller feeders

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Minimum pulling capacity 3 kg Machine made from stove-enamelled sheet steel. Two wheels and two self-locking castors. Accommodates cable diameter min. Ø5mm, max. Ø14mm. Drum-locking system with toothed shaft. Six-way accumulator ...

Machine for introducing fabric into digital printing machines Axial unwinder column It allows unwinding of big rolls at constant speed and tension. Enlarger and centring device Dogal 03 For tissue centring and stretching, with ...

... SUPERIOR TECHNOLOGY Shuttle Feeder. Interchangeable with rotary feeders. Allows for in-line feeding of products. Miss detection and electromagnetic clutch for selective control. Vacuum designed shuttle ...

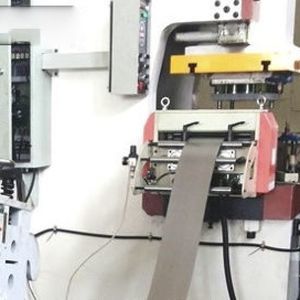

... high-speed roller feeder is a type of feeding machine used in the metal stamping process. It works by using an eccentric disk attached to the punch output shaft to drive the feeding rollers ...

... out. NC feeder is much more expensive than AF, but its feeding accuracy is really the highest performance among all kinds of feeder machine, and its life cycle is about 10+ years. Compared to mechanical ...

Automatización de Prensas, S.L. manufactures electronic roll feeders for metal strip coils with widths from 110-1700 mm for maximum cross section of 3000 mm² , covering a wide range of solutions for sensitive materials ...

... fines and a uniform feed rate. In heavy duty, high capacity applications, the wobbler is often fed from a heavy duty apron feeder.

The TS 13 ST/AL Autofeeder series is composed of systems that automatically feed seamers and conversion presses with ends previously stored inside trays. This system is the complementary solution for the Autopacker and makes component ...

... feeding precision. A mounting plate can help the servo feeder install to press machine easily. Or you can choose a separate bracket for better stability. RNC-400B Precision servo roller feeder ...

Zigzag NC servo Feeder is designed tO Tor circle blanking line, with high efficient processing and save material utilization function. It can be suitable for all kinds of circle, round cover and washer stamping. Zigzag ...

Shenzhen Sunrui Machinery Co., Ltd.

... The Electronic feeder model MA 126 is constructed in the following tape widths:100 mm – 200 mm – 300 mm – 400 mm – 500 mm • The Electronic feeder model MA 126 can feed sheet metal with a maximum thickness ...

Electronic roller feeds from ebu are designed for fast and precise feeding of the strip material into the press: the material is transferred into the machine via two parallel stacked rollers rotating ...

... view availability The feeder from PME are characterized by high repeat accuracy and dynamic application options. Both feed rollers are driven by the three-phase servo motor with zero backlash via planetary ...

The microfeeder are specially designed to enable the complete processing of the final part of the coils and are combined with presses with progressive die, transfer and blanking. Positioned between the feeding rolls and the die, the ...

... automatically extract water vapor to improve production conditions and stabilize production operations. ★Compound pressure roller structure, its eccentricity and wear clearance can be adjusted to improve the utilization ...

Henan Oreco Environmental Engineering Technology C

Zigzag NC servo feeder Zigzag NC servo Feeder is designed to for circle blanking line, with high efficient processing and save material utilization function.It can be suitable for all kinds of circle, ...

MAYFLAY Machinery (Huizhou) Co., Ltd.

The feeders are offered on request: the design and study is performed according to type of piece, production, optimizing handling, cycle time, with control option of piece (before and after machining) always considering ...

... capacity of FC30, FC35 and FC45 case erctors. Cases are loaded laid and feeded thanks to two motorized chains mounted on a mobile motorized holder. An adjustable case support side makes the alignment easier when cases ...

Bortolin Kemo

- All kind of fabrics, included elastic fabrics - Working width: Min.1800mm - Max.2000mm - Inlet: Small roll, big batch and/or plaited - Collecting belt: from 2000 to 4000 mm - Diameter roll: max. 500 mm - Speed: adjustable from 0 to 80 m/min

... . ● 3 OR 4 ROLLERS MODELS FOR SELECTION AND 4 OR 8 FEEDING SPEEDS AVAILABLE FOR UTILITY. ● ANGLE FEEDING IS POSSIBLE WITH ALL MODELS. THEY CAN BE MOUNTED ERTICALLY, HORIZONTALLY OR AT ANY ANGLE FOR AN EASY OPERATION. ● ...

The automatic feeder ALM010 is suitable for high-productivity lines and for production of medium and large size tiles from 30x30cm to 60x120cm. This feed the automatic cutting, edging board, polishing and grinding lines, ...

Servo Roll Feeder Previously unattainable high-precision numerical control is made possible by CCS (computer controlled servo), for fast and accurate performance.

... and desired throughput Bauermeister Roller Mills can be equipped with different dosing systems. The Bauermeister Roll Feeding Devices WSV (One- or Two-Roller Feeder) were specially designed ...

... continuously that takes a stack of cards or sheets and separates them into a single pitched stream onto a conveyor. An ideal feeder for any industries which need to put the instructions, tag, envelope, card, bag and so ...

... , 3 rubber feed rollers, vertical and horizontal support columns, universal joints and lubricating gun. Features • Rugged, efficient drive system. Continuous-duty motor powers the lubricated gear box, which transmits ...

*Fits LT24 and above. Specs: 10 speeds from 3 Fpm to 45Fpm 1/2HP 220 volts 1 phase

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining