- Packing - Handling - Logistics >

- Conveying >

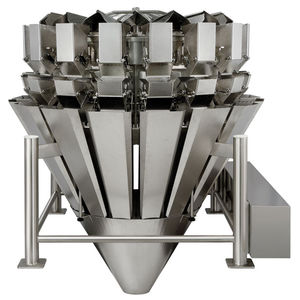

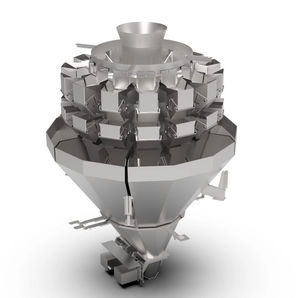

- Weighing machine for the food industry

Weighing machines for the food industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The weighing and dosing systems are based on dosing or linear multihead weighers. Designed to be the ideal solution for maximum versatility, speed-accuracy requirements without underestimating the ease of maintenance ...

... a high weighing capacity of up to 80 t/h is achieved with low space requirements. The weighers are verifiable and are supplied with calibration weights on demand. For the green coffee sector, the ...

Roasting loss control scales are an important element in the evaluation process of the roasting result. By weighing the batch, the roasting loss caused by changes in the moisture content ...

Production speed: 1,000, 200 p/h

... or conveyor • vibrator table • Conveying device The heart of the ELEMENTRA® is the standard MEC 4.0 weighing electronics which controls the weigher and networks all the individual ...

Production speed: 400 p/min

High-speed and high accuracy multihead weighing performance The RV is the most advanced multihead weigher in the world, with the widest application scope offered in the industry. Not ...

Ishida Europe Limited

Weighing and controlling is one of the most common procedures in process automation and BAADER offers both standard and custom models to meet customers’ requirements. The key element in any grading ...

Production speed: 6 p/min - 10 p/min

The Cabinplant batch weigher is designed to weigh a variety of different products, e.g. whole frozen fish, frozen shrimps or frozen vegetables into cartons, boxes, bags or sacks. The batch weigher ...

Cabinplant A/S

Production speed: 10 p/min - 15 p/min

For weighing products such as: short pasta, dried fruit, biscuits, sweets, chocolates, frozen vegetables, granular coffee / cocoa, salt, pulses, rice, pet food, seeds, nuts and bolts etc. Technical ...

... clean reducing downtime. ■WEIGH SENSOR The load cell level detector under the top cone controls the product flow from the scale feeder ensuring proper feed conditions to maximize efficiency and accuracy. The color touch ...

Yamato Scale Co

Production speed: 50 p/min - 100 p/min

Multihead weighers High performance, high speed multi head weighers, suitable for weighing bulk goods like pasta, rice, cereals, sweets, candies and much else Multihead weigher 10 • ...

... combination weigher available with small, medium and large volume hoppers for extremely high-speed applications with lowest give-away. One of a suite of food weighing solutions for ...

continuous weighing machineAVN 112-CW 12EV-K

Production speed: 8 p/min - 60 p/min

The weighing machine AVN 112-CWEV-K weighing machine has been especially developed for the weighing of carrots. The weighing buckets ...

Affeldt Maschinenbau GmbH

Production speed: 60 p/min - 280 p/min

... multi-head weigher intended for use on the food industry. It is equipped with a multimedia software that is based on Windows and it can be controlled through a remote. In addition, this ...

PFM Packaging Machinery

Production speed: 10 p/min

Max. Weighing: - 1,500g Accuracy: - X (0.5) - Hopper Volume: - 3.0L High Light: - Linear Single Head Weigher, 3.0L Single Head Weigher Application: Applicable for weighing of ...

Zhongshan TO-U Packaging Machinery Co.,Ltd

Production speed: 65, 120 p/min

... / 14 Heads Multihead Weigher is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins ...

Foshan Coretamp Packaging Machinery Co., Ltd

Production speed: 15 p/min - 40 p/min

... linear weighers are independent devices, which are normally mounted to the packaging machines and work together with them. The main function of the dosing device is the separating of the product into ...

Production speed: 45, 35 p/min

• Associative weighing machine with 15 large rotating buckets and only 1 load cell. • The PA-25 uses a large color LCD touch-screen that allows easy programming and monitoring. • Automatically adjusts ...

Talleres Daumar S.L.

... designed to achieve accurate weighing of your ingredients time after time. Our offerings include both gain in weight and loss in weight systems, in order to assist in accuracy and also to control ingredient batch weighing.

Frequently in pharmaceutical environments, one must often separate the source package from the target package. This and many other challenges to secure, traceable and ergonomic weighing are ensured by ...

... product very accurately for package filling. Constructie Bruynooghe provides stainless steel frame for installation of partner machine. Customer brand choice. Advice by our engineering office. Construction ...

The linear weighers are incorporated as a dosing system in COALZA's vertical packaging machines to obtain the net weight of all kinds of products from 20 to 5,000 grs and with a volume of up to 25 litres. How ...

Production speed: 500 p/h - 2,000 p/h

The universal weighing multihead linear doser VD-1-4 is designed for accurate and quick dosing of granular products in packages or in loading bunker for packaging. It may be configured in modifications from one to four ...

PACKING TECHNOLOGIES LLC

... feeder design eliminates flow control variables. • Weigh mode retained with each program - switch from grams to pounds to ounces, etc. at the touch of a key. • All contact surfaces quick disconnect ...

The CALIBRA WEIGHER.F12 weighing machine has been designed to improve the productive capacity of our clients. Its robust structure linked to state-of-the-art technology enables fast and smooth handling ...

• New updated version of the bestseller weighing machine AM322-AM422 • Easy to operate with TOUCH panel • Automatic cycle with multiple belt speeds • Adjustable belt speeds, optimizing precision / ...

Production speed: 360 p/h - 500 p/h

Electronic Quantitative Packing Scale for 25kg sunflower seeds is suitable for the quantitative packing of granule,fodder,bean,grain,chemical material .Type: Single scale PRODUCT DESCRIPTION The ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining